Mini Meat Strip Cutting Machine

Main Benefits

- Great cutting precision compared to manual work

- Gives maximum output without waste

- Hygienic production process

- Efficient, safe operation and easy maintenance

- Easily handle by one operator

Overview

Mini Meat Strip Cutting Machine

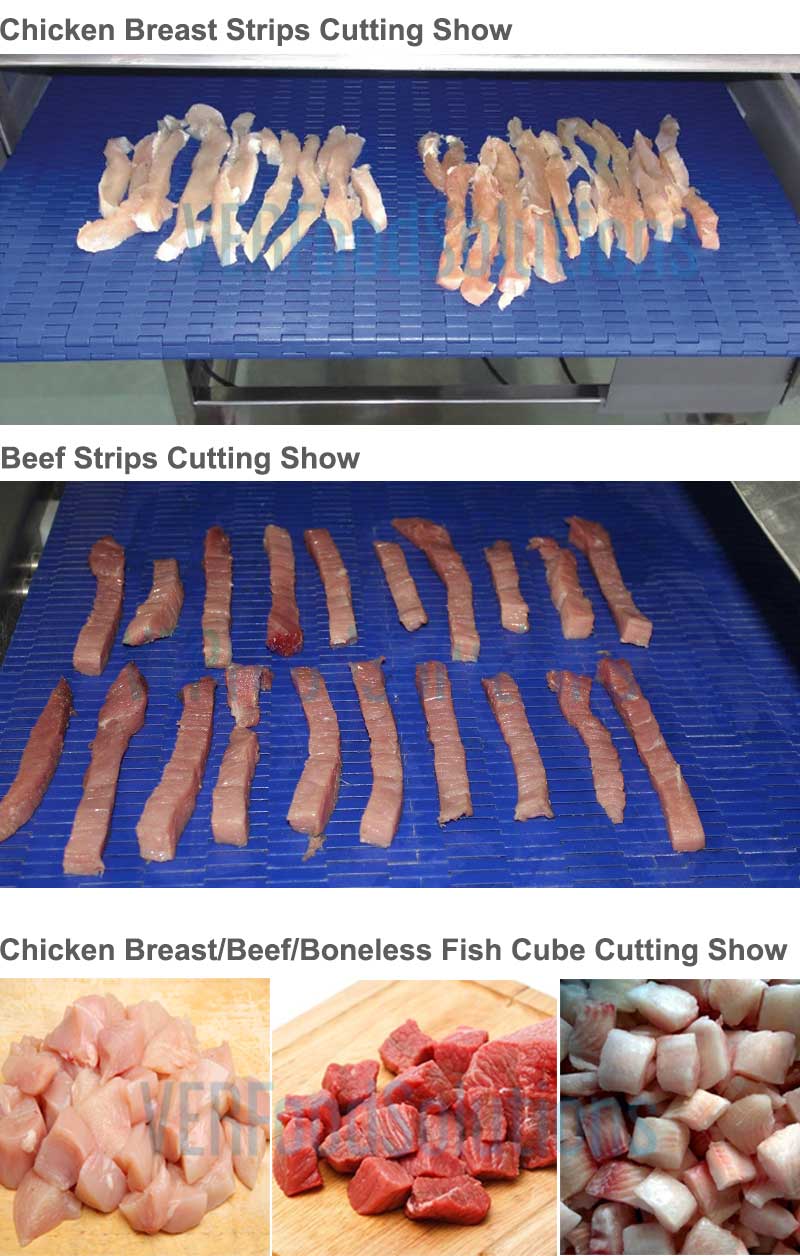

VER Mini meat strip cutting machine score high with their various processing possibilities: beef meat, pork, poultry, chicken breast, boneless fish meat and many more products can be cut perfectly and hygienically into strips or cubes. With a wide variety of sized cutting heads, it is suited with every application, increasing and improving your products presentation and increase your productivity.

Videos

Features

- High cutting precision

- Smart system for sorting

- Up to two lane operation

- Perform in-feed and out-feed automatically

- Meet small capacity meat processing demand

- Recommended for boneless and fresh meat cutting

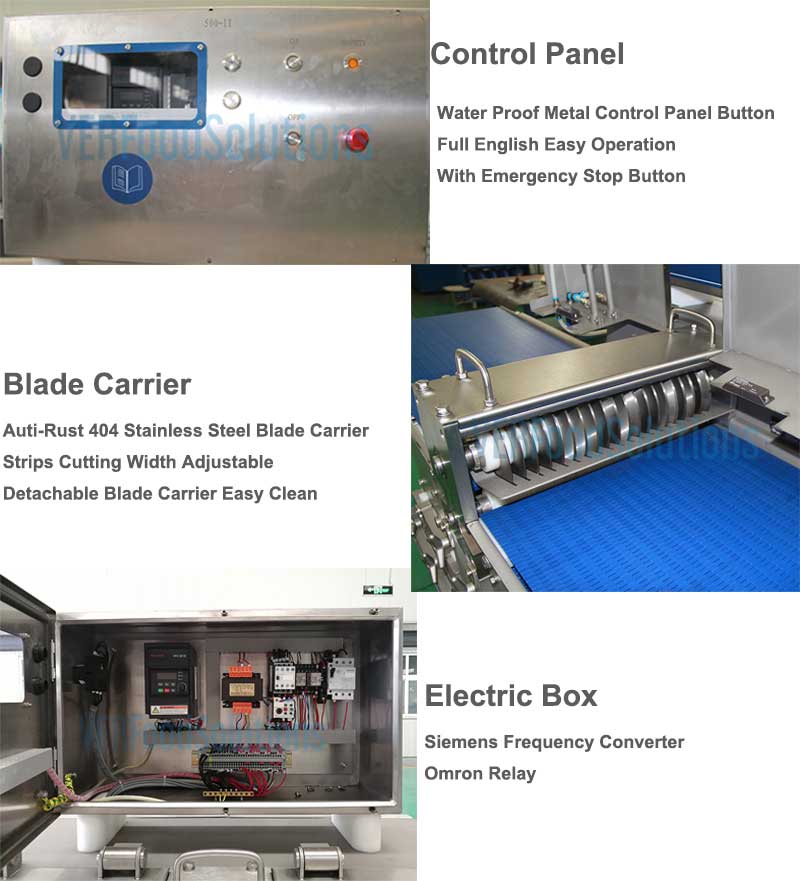

- Made in stainless steel and other non-corrosive materials

- HACCP and CE authorization

1.Mini Meat Strip Cutting Machine Cutting Strips and Cubes Effect Show

2.Mini Meat Strip Cutting Machine Detail Parts Introduction

3.Mini Meat Strip Cutting Machine can be connected with Single Lane Horizontal Slicer as a whole process line.

Specifications

- ModelSCD200

- Mesh Belt Width(mm)200

- Mesh Belt Speed(m/min)3-18

- Max Meat Width(mm)160

- Min Cutting Thickness(mm)5

- Max Cutting Thickness(mm)45

- Productivity Capacity(Kg/h)50-200

- Cutting Height(mm)1050±50

- Power(Kw)0.6

- Dimension(mm)1200*450*1000

FAQ

Why should I order one mini meat strip cutting machine?

Mini strip cutting machine can cut down a huge labor cost which you pay hourly/weekly/monthly and also increase the production rate up to 100x than a normal person. This meat strip cutter is highly recommended for small good stores, supermarkets, butcher shops, industrial kitchens, the wholesale sector and other meat productions.

What about the productivity for this mini meat strip cutting machine?

VER strip cutter can cut meat as strips, by changing its cutting blade set it can cut various width. It can cut 50-200kg per hour, very suitable for start meat processing factory.

How to clean the strip cutting machine?

Whenever you planned to clean the machine, make sure all the plugs are disconnected and blades cover are closed. Move the machine somewhere in the middle far from the switches so no electric shock occur. Mild warm water is recommended with a soft cloth, also you can apply detergent on the surface. Our machines have:

• All stainless steel construction and sanitary design

• There are no bolts or nuts in the cutting drum or product area.

• There are no sharp edges or projecting parts, thus effectively

• eliminating “dirt-traps”.

• All welds are continuous and polished

Is it safe to operate this strip cutting machine?

It is both safe on operation and food standards to use this strip cutting machine. Full automatic feeding and slicing, equipped with a low voltage control relay, thermal relay and a direction control switch. All these factors helps to prevent operators from industrial accidents, also guarantee consistent meat quality.

What warranty do you offer?

One-year standard warranty applies on strip cutting machine. Extra spare parts are also delivered in the same package.