Why Should I Buy One Grill Marker Machine?

July 18, 2024Admin

VERFOODSOLUTIONS grill marker machine are transforming the food industry with their ability to enhance product appeal through precise surface carbonization and marking. These innovative devices, known as ‘bar-markers’, offer VERFOODSOLUTIONS satile applications across a wide range of food products, from raw to fully cooked, chilled, or frozen items. The VER grill marker machine stands out for its adaptive surface marking technology and evenly applied grill marks, ensuring consistent patterns that enhance visual appeal and perceived flavor. With precision-controlled dual-zone grilling and temperatures up to 500°F (260°C), these machines offer unparalleled flexibility in creating distinct flavor profiles and textures.

Safety, efficiency, and versatility are at the core of this technology. The machine’s design minimizes the formation of harmful substances during grilling, while offering options for single-sided or double-sided marking and a choice between gas or electric heating. Its efficient, hygienic, and versatile production capabilities make it an ideal solution for various food manufacturing environments. From enhancing the appearance of meat and poultry to creating authentic-looking grill patterns on plant-based alternatives, the grill marker machine offers endless possibilities for food manufacturers looking to elevate their products’ market appeal. With seamless integration into existing production lines and a user-friendly interface, it has become an indispensable tool in modern food processing, ensuring safe, reliable, and efficient grilling operations. Let’s explore in detail the numerous benefits and advantages that investing in a grill marker machine can bring to your food production business.

Enhancing Product Appeal

The VERFOODSOLUTIONS grill marker machine stands as a pivotal innovation for food manufacturers aiming to elevate their products’ market appeal and perceived quality. This advanced machine’s primary strength lies in its exceptional ability to enhance the visual allure and implied flavor profile of food items. By applying authentic-looking grill marks to extruded products, the Grill Marker transforms ordinary items into visually captivating offerings that evoke the enticing char and smoky essence associated with traditional grilling methods. The machine’s dual grill marking units, coupled with high-intensity heating elements, ensure rapid and uniform heating of the grill plates, resulting in precise and consistent grill marks across entire production runs. This uniformity is further refined through adjustable settings for temperature and dwell time, allowing manufacturers to tailor the grilling process to various food products with meticulous precision. The availability of different ring widths adds another layer of customization, ensuring that the grill marks enhance the product’s appearance without compromising its structural integrity. The visual enhancement achieved by the Grill Marker goes beyond mere aesthetics; it triggers positive taste associations in consumers’ minds, potentially influencing their perception of flavor even before consumption. This powerful first impression can significantly impact consumer choice and satisfaction, setting products apart in a crowded marketplace.

Adaptive Surface Marking Technology

The grill marker machine showcases remarkable VERFOODSOLUTIONS satility in surface adherence, accommodating products of various shapes and sizes without requiring pre-flattening. Its innovative design, featuring a flexible suspension system and compact upper marking rollers, ensures uniform grill patterns on diverse product surfaces while preserving their original form. The grill marker’s adaptable design ensures that various products, including cylindrical or irregularly shaped vegetables and fruits such as maize, courgettes, carrots, and apples, can be processed while fully maintaining their original morphology. The electrically heated rollers offer the flexibility to mark either one or both sides of products, with the ability to selectively deactivate rollers via the control cabinet. This adaptable functionality allows for precise, customizable marking on a wide range of items, making the grill marker an indispensable tool in versatile production environments where consistent, high-quality surface marking is essential.

Versatile Product Thickness Accommodation

The grill marker machine demonstrates exceptional versatility in processing a wide range of product thicknesses, adjustable height of the grill marker and brander to correspond with the height of the product as well as the height of the inline conveyor. Versatile Product Thickness Accommodation Its sophisticated design incorporates two heating drums, strategically positioned to process items evenly distributed on the stainless steel belt. The equipment’s adaptability is further enhanced by its user-friendly adjustment capabilities. Operators can manually modify the height of the upper heated roller relative to the lower one, ensuring optimal positioning for various product thicknesses. Additionally, the control panel offers precise regulation of critical parameters, including marking roller rotation speed, infeed/outfeed conveyor velocity, and the desired surface temperature of the marking roller. For fine-tuned adjustments, a handwheel mechanism facilitates manual control of roller height, allowing for meticulous calibration to achieve optimal marking results across diverse product profiles.

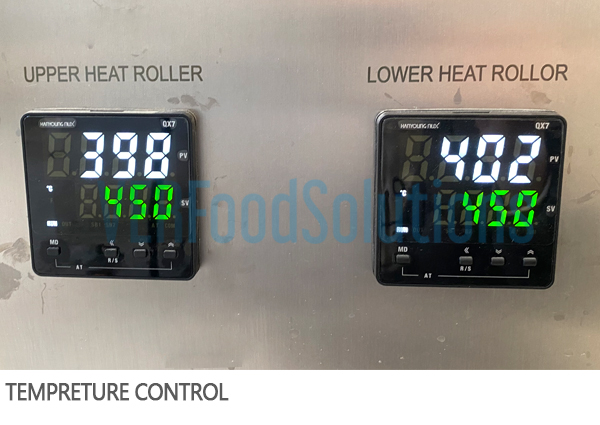

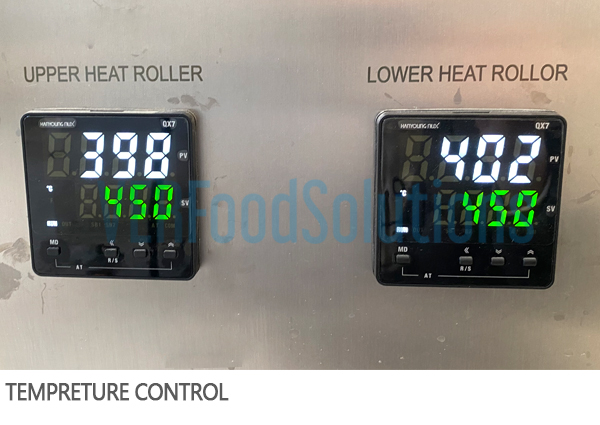

Precision-Controlled Dual-Zone Grilling

The VERFOODSOLUTIONS grill marker machine excels in its advanced temperature control capabilities, offering unprecedented precision and flexibility in the grilling process. Each of the machine’s two food-grade steel rollers can be independently programmed, allowing for temperatures to be set with pinpoint accuracy up to 500°F (260°C). This granular control enables operators to create distinct temperature zones, tailoring the cooking environment to the specific requirements of different products. For instance, one could configure the upper roller to operate at a lower temperature, such as 350°F (177°C), for gentle surface treatment, while simultaneously setting the lower roller to a higher temperature, like 490°F (254°C), for more intense heat application. This dual-zone heating approach facilitates the separation of maturation and flavor development processes, allowing for nuanced control over product texture, taste, and appearance. Such precise temperature management not only enhances product quality and consistency but also opens up new possibilities for product innovation and differentiation in the competitive food manufacturing landscape.

Versatile Grill Marking Options

The VERFOODSOLUTIONS grill marker machine offers unparalleled flexibility in grill marking applications, allowing manufacturers to select between single-sided and double-sided marking processes. This versatility enables the creation of diverse visual presentations tailored to specific product requirements or brand aesthetics. In single-sided mode, the machine can apply either horizontal or vertical stripes, providing a classic grilled appearance. Alternatively, when operated in double-sided mode, it simultaneously marks both sides of the product, facilitating the creation of intricate cross patterns for a more elaborate presentation. This dual-functionality not only enhances operational efficiency by reducing processing time for double-sided marking but also expands the range of achievable designs. Whether aiming for a subtle grilled effect or a more pronounced pattern, the machine’s adaptability ensures that food manufacturers can achieve the desired visual impact across various product types, from delicate fish fillets to robust meat cuts.

Versatile Heating: Gas or Electric

The grill marker machine offers dual heating options, accommodating both gas and electric power sources to suit diverse operational needs. Electric heating provides precise temperature control, clean operation, and easy installation, making it ideal for environments requiring consistent heat or adhering to strict emissions standards. Conversely, gas heating offers faster heat-up times and potentially lower operational costs in areas with favorable natural gas prices, making it suitable for high-volume production. The choice between gas and electric heating should be based on factors such as local energy costs, production requirements, and environmental considerations, ensuring optimal efficiency and cost-effectiveness for your specific grill marking operations.

Efficient, Safe, Reliable Grilling

Our VERFOODSOLUTIONS grill marker combines ease of operation with advanced safety features and reliable performance. Its intuitive interface allows for precise customization of grill patterns and cooking times, while the integrated PLC ensures optimal temperature control to prevent charring. Built with durable, food-grade materials, this versatile equipment streamlines the grilling process, consistently producing high-quality grill marks on various food products. Multiple fail-safe mechanisms and emergency shut-off systems prioritize operator safety in industrial settings. With low maintenance requirements and high productivity, this grill marker is an essential asset for any food production line, offering a perfect balance of efficiency, safety, and reliability.

Seamless Production Line Integration

The grill marker machine offers exceptional versatility and ease of integration into diverse production environments. Available in standard belt widths of 600, 800 and 1000mm, with custom options available, it adapts effortlessly to various cooking equipment configurations. Its caster-equipped design facilitates simple positioning and connection to upstream machinery, while the adjustable belt height ensures perfect alignment with adjacent units. Compatible with a wide range of cooking apparatus, including continous fryers, steam ovens, and contact cookers, this grill marker seamlessly incorporates into comprehensive production lines. The adaptable height of the grill marker and brander components accommodates different product sizes and aligns precisely with inline conveyors, enhancing overall production efficiency and flexibility.

Versatile Food Industry Applications

Grill marker machines have revolutionized various sectors of the food industry by providing a precise and efficient method for adding visually appealing grill marks to a diverse range of products. This innovative technology finds applications across multiple categories, offering consistency and aesthetic enhancement to culinary creations. Handling raw, cooked, refrigerated or frozen products, these machines demonstrate remarkable versatility.

-Meat, Poultry & Fish:

• STEAKS & CHOPS: Ensuring uniform, appetizing grill marks that signify quality and proper preparation.

• BURGERS & SAUSAGES: Enhancing visual appeal and suggesting a flame-grilled flavor profile.

• CHICKEN BREASTS: Creating consistent grill patterns that improve presentation and perceived value.

• FISH FILLETS: Imparting professional-looking sear marks, elevating the product’s appearance and suggesting expert preparation.

-Fruits & Vegetables:

• ZUCCHINI: Adding attractive grill lines that improve visual appeal and suggest a grilled flavor.

• EGGPLANT: Creating uniform sear patterns that enhance texture and presentation.

• Other vegetables: Suitable for sliced peppers, onions, courgettes, etc.

-Plant-Based Foods:

• TOFU: Imparting grill marks that mimic traditional grilling, enhancing appeal for vegetarian and vegan consumers.

• PLANT-BASED FOODS: Creating authentic-looking grill patterns on various plant-based alternatives.

-Bakery Goods & Confectioneries:

• Bread products such as Panini and Ciabatta

• Pastries and cookies

-Pet Food & Treats:

• Creating appealing textures and patterns on pet food and treats.

The versatility of these machines extends to various food items, ensuring consistent grill marks that not only enhance the visual appeal but also signal quality and flavor across diverse product categories.

In conclusion, investing in a VERFOODSOLUTIONS grill marker machine offers numerous advantages that can significantly elevate your food production business. From enhancing product appeal through precise and consistent grill markings to ensuring safety and efficiency in grilling operations, this innovative technology stands out for its adaptability across a wide range of food products. Whether you’re looking to improve the visual attractiveness of meat, poultry, and fish or add professional grill patterns to fruits, vegetables, and plant-based alternatives, the VERFOODSOLUTIONS grill marker machine delivers exceptional results. Its dual-zone grilling capability and versatile heating options cater to diverse production needs, while its seamless integration into existing production lines enhances overall efficiency. By prioritizing quality, hygiene, and operational flexibility, this machine not only enhances product aesthetics but also supports consumer perception of superior taste and quality. Don’t miss out on this opportunity to take your food business to the next level – invest in the VERFOODSOLUTIONS grill marker machine today and discover the possibilities for yourself!

Views: 348

Leave a Reply