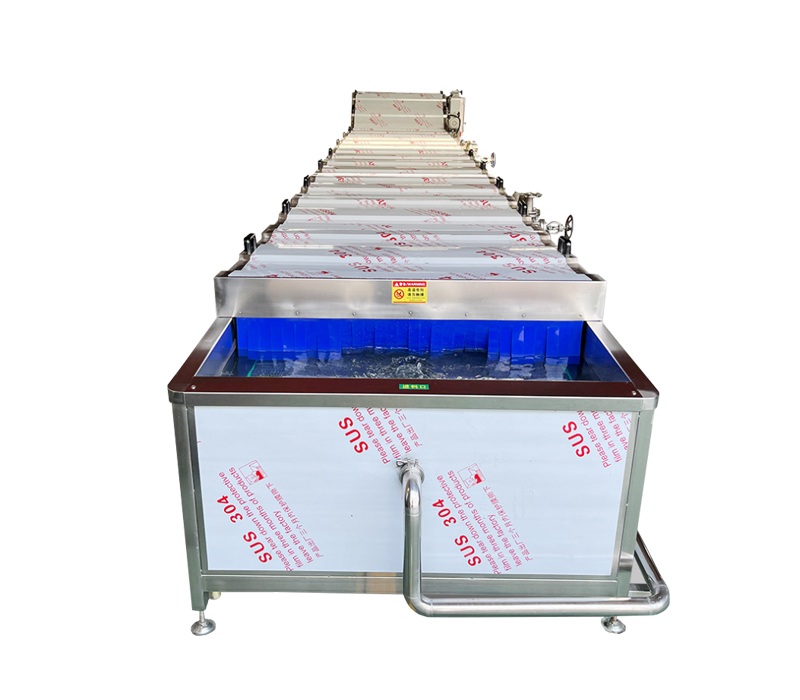

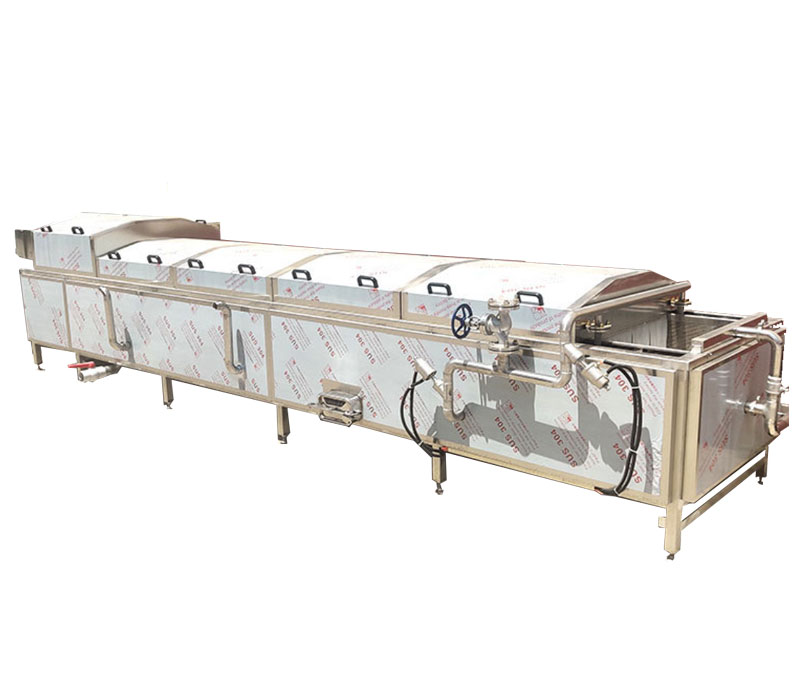

Pasteurizer Machine

Main Benefits

- Optional electric or steam heating way

- Optional lifting system for easy cleaning

- Temperature& belt conveyor speed adjustable

- Small temperature error, using temperature sensor

- Waterproof sealing cover keep steam, no burns

- Three-stage steam heating provides uniform heating control

- Customizable designs for machine length and width

- High-strength mesh belt resists deformation and maintenance

- Inhibits enzymes, preserving food’s natural color and flavor

- Double-layer design ensures thorough product sterilization

- Effectively eliminates microbes, ensuring food safety and quality.

- Low-noise operation enhances overall working environment

- Efficient design significantly reduces energy consumption

- Multiple cleaning ports enable fast drainage and maintenance

- Automation reduces labor demand and operational costs

Overview

The pasteurizer machine employs two types of heating methods: electric heating and steam heating. The principle behind pasteurization is that within a specific temperature range, lower temperatures slow bacterial reproduction while higher temperatures accelerate it. If the temperature exceeds a certain point, the bacteria will be eradicated. Different bacteria thrive at different temperatures and exhibit varying degrees of heat and cold resistance. Pasteurization leverages the fact that most bacteria are not very heat-resistant, using optimal temperatures and holding times to ensure their complete elimination. However, a small number of harmless or beneficial bacteria, including some heat-resistant spores, may still remain after the process. In industries such as food, beverages, and pharmaceuticals, certain packaged products need to be sterilized using a water bath method. These products are placed on a stainless steel mesh belt with adjustable speed and are conveyed in sequence into a sterilization chamber. Here, they are sterilized using “high-temperature water as the medium,” and subsequently transferred to a cooling box via the conveyor belt for even cooling, thereby satisfying sterilization requirements. This entire system operates continuously, allowing sterilized packages to move seamlessly to the next production stage. The temperature and speed can be tailored according to process specifications, ensuring smooth operation. Built from high-strength stainless steel, the mesh belt is designed for durability, low elasticity, minimal deformation, and ease of maintenance.

Videos

Features

- Electric or steam heating available for versatility.

- Fully automatic for loading and discharging.

- Circulating pump ensures uniform temperature in blanching pool.

- Food-grade SUS304 stainless steel ensures safety and compliance.

- Adjustable blanching temperature and speed for quiet operation.

- Adjustable temperature settings up to 99°C.

- Three-stage steam heating ensures precise temperature management.

- Rock wool insulation prevents heat dissipation effectively.

- Circulating filter tank minimizes water waste resources.

- Automatic cold water circulation maintains stable temperature control.

- Double-layer mesh belts ensure optimal immersion and flow.

- High-strength stainless steel mesh belt is durable and maintainable.

- Variable frequency motor adjusts speed from 4 to 21 minutes.

- Overflow system prevents liquid spillage during operation.

- Anti-floating system ensures complete immersion for sterilization.

- User-friendly electrical control system simplifies functionality.

- Inclined design with large sewage outlet simplifies maintenance.

Specifications

| Manual Basket | Model | BPM-500 | BPM-1000 | BPM-1500 | BPM-2000 |

| Heating Method | Electric/Steam | Electric/Steam | Electric/Steam | Electric/Steam | |

| Electric Power(Kw) | 9 /0.2 | 24 / 0.2 | 36 / 0.2 | 60 / 0.2 | |

| Capacity(Kgs/Batch) | 10-15 | 20-30 | 30-50 | 50-100 | |

| Dimension(cm) | 70*70*95 | 120*70*95 | 178*70*95 | 2320*70*95 | |

| Machine Weight(Kgs) | 60 | 100 | 150 | 200 |

|

Automatic Continuous Belt Type | Model | BPM-2500 | BPM-3000 | BPM-4000 | BPM-5000 | BPM-6000 | BPM-7000 |

| Heating Method | Electric/Steam | Electric/Steam | Electric/Steam | Electric/Steam | Electric/Steam | Electric/Steam | |

| Electric Power (Kw) | 9 /0.75 | 24 / 0.75 | 36 / 0.75 | 60 / 0.75 | 36 / 0.75 | 60 / 0.75 | |

| Capacity (Kgs/Batch) | 600-750 | 800-1000 | 1000-1300 | 1300-1600 | 1500-1700 | 1700-2200 | |

| Belt Width (mm) | 700 | 700 | 800 | 800 | 800 | 800 | |

| Dimension (cm) | 270*100*130 | 320*100*130 | 420*120*130 | 520*120*130 | 620*120*130 | 700*120*130 | |

| Machine Weight (Kgs) | 300 | 400 | 600 | 750 | 900 | 1100 |

FAQ

What is the application of the pasteurizer machine?

The pasteurizer machine is versatile and can be used in various fields, including:

– Bottled and canned products

– Fruits and vegetables

– Pickles

– Dairy products

– Snack foods

– Low-temperature meat products

Blanching is used mainly for fragile items like wild vegetables, root vegetables (like carrots and asparagus), mushrooms, and fruit slices, serving as an essential step for quick freezing and dehydration.

Sterilization is crucial for ensuring the safety of food and extends shelf life by effectively killing harmful microorganisms. This process is suited for low-temperature meat, canned fruits, vegetable juices, pickles, jams, and more.

The machine accommodates various packaging types, including vacuum-sealed foods, soft bottles, and glass jars.

What is the installation and setup procedures for the pasteurizer machine?

1. Equipment Placement:

Level the equipment feet at the designated location.

2. Utility Connections:

Connect water lines and electrical circuits.

3. Power Configuration:

Ensure correct power phase sequence; the green light on the phase sequence relay should be on.

4. Steam and Air Connections:

Connect the steam pipeline (pressure: 0.4 – 0.7 MPa).

Connect compressed air and adjust the relief valve (pressure: 0.6 – 0.8 MPa).

5. Temperature Adjustment:

Set the desired operating temperature.

6. Speed Adjustment:

Adjust conveying speed to required levels.

What are the steps for operating a pasteurizer machine?

1. Fill the water tank with water until it reaches the overflow port.

2. Turn on the power and activate the steam switch.

3. Add the raw materials, such as green leafy vegetables and cans.

4. Collect the processed materials.

What precautions should be taken when using the pasteurizer machine?

1. Avoid high-temperature burns from hot water, steam, and materials at the outlet while the equipment is running.

2. Do not insert your hands into the chain while the equipment is operational.

3. Do not adjust the conveying speed when the equipment is stopped.

4. The heating function should only be activated when the water tank is full.

What is the troubleshooting guide for pasteurizer machine?

1. Fault: Steam does not heat

Reason: Compressed air is connected incorrectly

Solution: Adjust the connection of the compressed air

2. Fault: Trap does not discharge water

Reason: Trap is clogged

Solution: Clean the trap

3. Fault: Chain conveyor is stuck

Reason: Mesh belt is too loose

Solution: Tighten the mesh belt

4. Fault: Water temperature does not reach the set temperature

Reason: Insufficient steam or clogged steam pipe

Solution: Increase air intake and clean the steam pipe

5. Fault: Water pump makes abnormal noise

Reason: Pump head is clogged

Solution: Remove foreign matter from the pump head