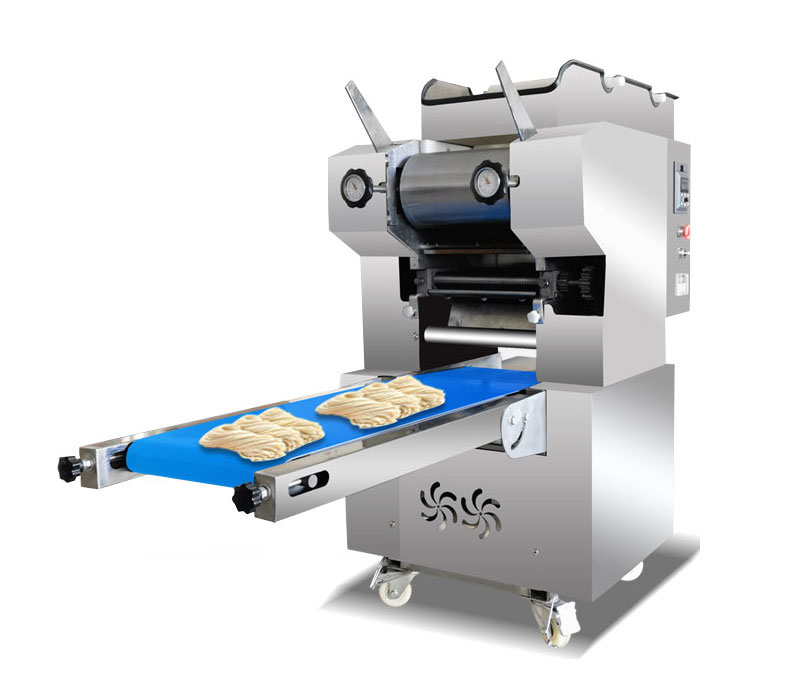

Ramen Noodle Machine

Main Benefits

- Multi-function: makes various types of Japanese and wide noodles.

- Efficient: consumes only 1 KWh of electricity per hour.

- Quick molding: forms sheets in just 8 seconds, enhancing taste.

- Automated: cuts, powders, and rolls to minimize manual effort.

- High durability: designed for long life with robust rollers.

- Quality materials: corrosion-resistant gears and chains ensure lasting performance.

- Flexible adjustment: adjustable cutting length; movable with built-in casters.

- Sanitary and safe: food-grade materials; easy to clean thoroughly.

- Time-saving: automation improves efficiency and maintains consistent quality.

- Easy operation: one-button start for precise adjustments and simplicity.

- Quiet operation: low noise, perfect for quiet environments.

- Safety protection: high temperature power-off ensures safe usage.

- High quality: made from durable 304 stainless steel for longevity.

Overview

VERFOODSOLUTIONS Japanese Ramen noodle machine utilizes advanced technology to provide an efficient and convenient Ramen noodle-making experience. Equipped with an energy-saving drive system, including a vector inverter and a reduction motor, it consumes only 1 kWh of electricity per hour, significantly reducing energy usage. The large-diameter 304 stainless steel pressing roller can be quickly formed by a single calendering process, saving time and effort, while ensuring the dough is even and smooth. The combination of automatic rolling and composite calendering technology makes the dough more chewy and resilient. During the rolling process, the machine can automatically sprinkle powder to prevent adhesion, ensuring every noodle is smooth and neat. The automatic cutting function allows the noodle length to be freely adjusted, greatly reducing manual cutting time.

Furthermore, the Ramen noodle machine is constructed with high-quality materials. The gears, scrapers, and chains are made of durable ductile iron and thickened brass, ensuring long-term, stable operation. The entire machine body is crafted from 304 stainless steel, which is both aesthetically pleasing and wear-resistant, easy to clean, and meets strict food hygiene standards. The precise hand-wheel adjustment system allows the dough thickness to be fine-tuned to accommodate different recipes. The silent design, featuring an all-copper reduction motor, ensures smooth, low-noise operation, suitable for various working environments. Equipped with mobile casters, the machine is easy to move and flexible to operate, meeting the needs of both commercial kitchens and home use. Whether you are a novice or a professional chef, this noodle machine can improve production efficiency and ensure every noodle has a perfect taste.

Videos

Features

- Efficient and simple control panel: The new control panel is responsive and easy to adjust.

- Efficient and energy-saving drive system: Equipped with vector inverter and motor, it consumes minimal power.

- Rapid prototyping technology: Large 304 stainless steel rollers enable efficient, waste-free flour forming.

- Automatic rolling and powder sprinkling: Dough is automatically rolled and powder-sprinkled to prevent adhesion.

- Automatic cutting function: Adjustable noodle length, uniform cuts, saving time and effort.

- Flexible noodle specification adjustment: Supports various knife and round knife size options.

- Precise adjustment: Hand wheel system allows easy, accurate dough thickness adjustment.

- Compound calendering function: Tighter gluten network for chewier, more elastic noodles.

- High-quality, durable materials: Ductile iron gears, thickened brass scrapers, and strong chains.

- Customized noodle knives: Supports various specifications to meet different recipe needs.

- Food-grade conveyor belt: Ensures noodles are not contaminated during processing.

- High-quality stainless steel body: Beautiful, wear-resistant, easy to clean and maintain.

- Silent design: All-copper motor, silent bearings, and gear transmission for smooth, quiet operation.

- Flexible movement: Mobile casters allow easy one-person positioning and adjustment.

- Intelligent safety protection: High temperature power-off function prevents overheating and damage.

Specifications

| Model | NM-168 |

| Power(Kw) | 1.1 |

| Cutting Blade Size(mm) | 1.25, 1.70, 2.00, 4.00mm(Customized) |

| Roller Size(mm) | Diameter 168 |

| Roller Width(mm) | 260 |

| Capacity(Kg/h) | 70-80 |

| Machine Weight(Kgs) | 260 |

| Machine Dimension(mm) | 1180*580*1150 |

FAQ

Why should I Invest in a Ramen noodle machine?

Investing in a Ramen noodle machine is a smart choice for factories and commercial kitchens, as it combines high efficiency, energy savings, and user-friendly operation. With a 168mm large diameter 304 stainless steel noodle roller, it produces smooth and chewy noodles in a single pass, while its high-performance vector inverter uses only 1Kwh of electricity per hour, making it more energy-efficient than traditional models. The machine automates wrapping, powdering, and cutting, streamlining operations and enhancing hygiene, while allowing precise control over noodle length, weight, and thickness. Its food-grade PVC conveyor belt and stainless steel body ensure safety and easy cleaning. Advanced composite rolling technology and hand wheel adjustments provide consistency in noodle texture, accommodating various recipes. With its durable, low-noise design and mobility features, this noodle machine is an ideal solution for restaurants, supermarkets, and commercial kitchens.

Can I adjust the length and thickness of noodles with the Ramen noodle machine?

Yes, you can easily adjust the length and thickness of your noodles with the Japan noodle machine, thanks to its convenient and precise adjustment functions. The Ramen noodle machine features a stepper motor timing cutting system, allowing users to control the cutter speed and cutting time for accurate noodle length. Additionally, the precision instrument scale handwheel makes it simple for both novices and experienced users to adjust dough thickness accurately. To ensure consistent dough quality, the machine supports a composite calendering function that enhances the dough’s toughness and gluten through two rounds of calendering, resulting in flat, smooth, and uniform thickness. Once the dough is formed, the automatic cutting system accurately slices noodles according to the set time and speed, ensuring consistency in length and weight while minimizing manual errors.

What should i do if my Ramen noodle machine isn’t working?

First, ensure that the power plug is properly connected and that the socket is functioning correctly.

If the power supply appears normal, the Japanese noodle machine’s power supply components may be damaged and will likely need to be replaced or repaired.

If the Ramen noodle machine has been used for an extended period, it may have overheated. Allow the machine to cool down before attempting to restart it. Check the overheating protection device if necessary.

What should I do if the Ramen noodle machine does not produce noodles?

If the flour is too dry and the Japanese noodle machine is unable to produce noodles, add a small amount of water until the consistency resembles that of peanuts before starting the machine.

If the flour is too wet and clumps together, you will need to break apart the dough and incorporate a suitable amount of dry flour until it reaches the correct consistency.

What should I do if the noodles are soft during Ramen noodle making?

Noodles may be too soft if no salt or alkali has been added. Incorporate an appropriate amount of salt or alkali to enhance the noodles’ texture.

Utilizing medium-gluten flour can help prevent excess water from being added at one time.

If the noodles become soft, you can slightly raise the height of the noodle outlet or sprinkle a little dry flour during production to prevent sticking.

How to avoid damage or blockage of Ramen noodle machine parts?

When operating the Japanese Ramen noodle machine, ensure that no hard objects are placed between the noodle rollers to avoid damage.

If the Japanese Ramen noodle machine will not be used for an extended period, apply a small amount of cooking oil to the surface of the rollers to prevent rusting.

Clean out any flour residue after each use to prevent buildup that could obstruct normal operation.

How to keep the Japanese Ramen noodle machine in the best working condition?

When using the Japanese Ramen noodle machine, gradually adjust the gap between the rollers from thick to thin to ensure optimal dough quality.

Never place your hands near the gap between the rollers to avoid accidental injury.

Regularly inspect and replace lubricating oil, gears, and other vulnerable parts to ensure the Japanese noodle machine operates efficiently over the long term.

How to clean and maintain the Japanese Ramen noodle machine on a daily basis?

To ensure the longevity and optimal performance of your Japanese Ramen noodle machine, follow these daily cleaning and maintenance steps:

1. Clean After Each Use: After using the noodle machine, thoroughly clean the interior to remove any flour and debris. Wipe down the machine casing with a damp cloth to prevent the buildup of oil and dust.

2. Avoid Direct Water Exposure: Do not spray the machine directly with water, as this can lead to moisture entering the interior and negatively impacting its lifespan.

3. Lubricate Key Components: Regularly apply lubricating oil to essential parts, such as the drive shaft and gears, to ensure the machine operates smoothly.

4. Check the V-belt: Periodically inspect the tightness of the V-belt. Adjust or replace it as necessary to maintain proper functioning.

By following these steps, you can keep your Japanese noodle machine in excellent working condition.