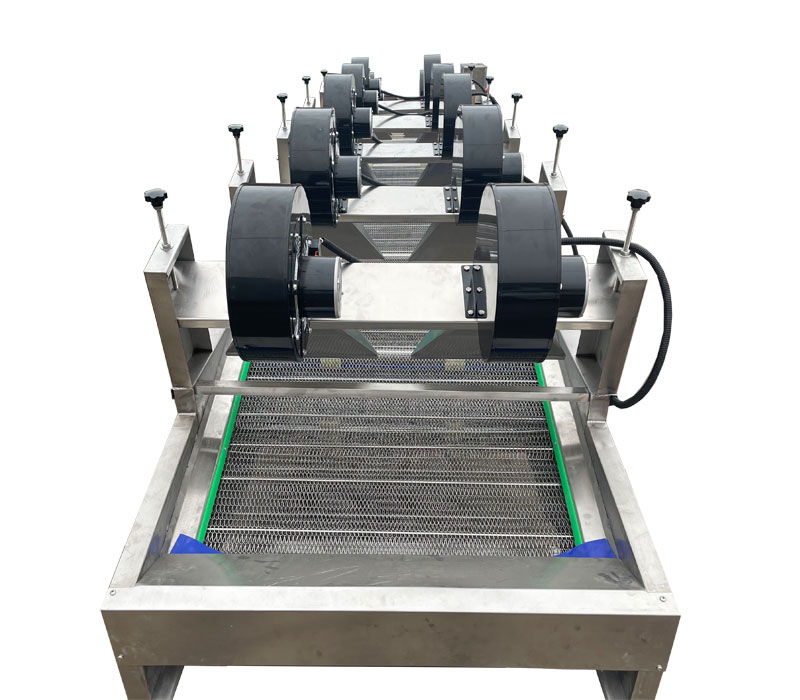

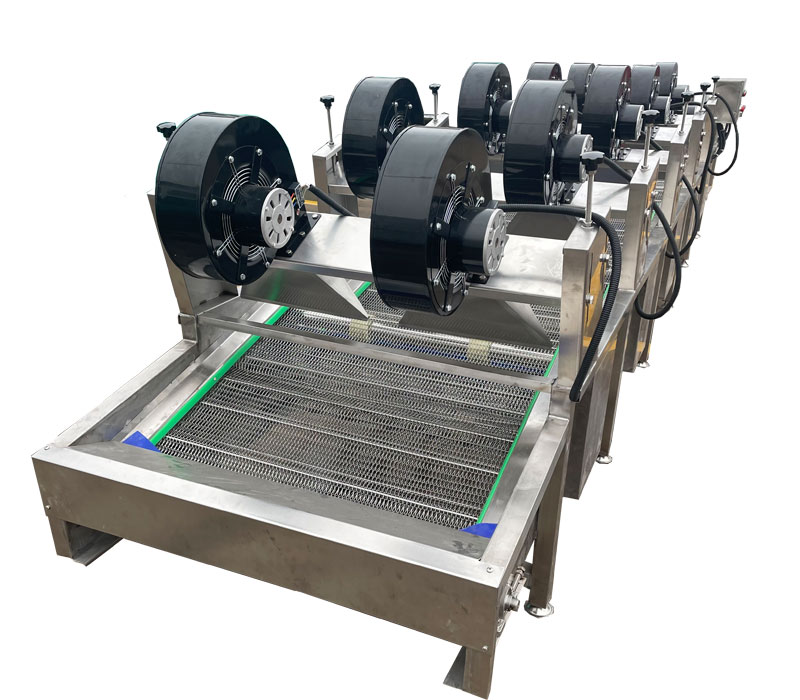

Flip Air Drying Machine

Main Benefits

- Caters to food and medicine industries.

- Automated processes reduce manual labor efforts.

- User-friendly controls for easy operation.

- Low-noise fan saves energy and costs.

- Stainless steel ensures safety and hygiene.

- Moisture removal extends product freshness and quality.

- Customizable speeds for various production needs.

- Compact design for durability and space-saving.

- Easily integrates with other assembly line equipment.

- Lowers contamination risk compared to traditional methods.

- Efficient drying reduces energy consumption significantly.

- Strong returns on investment from efficiency.

Overview

VERFOODSOLUTIONS Flip air drying machine is an advanced drying solution designed to optimize the drying process for soft-packaged foods, such as meats and vegetables. Utilizing a robust, low-noise fan that generates a large air volume, this machine ensures efficient and even drying by employing a multi-flipping mechanism that exposes each side of the packaged product to high-pressure, cold air. The innovative reverse wind device minimizes dead spots, ensuring comprehensive moisture removal and enabling quick evaporation of surface water, including moisture trapped in wrinkles of packaging. This feature is particularly beneficial after sterilization processes, making the dryer ideal for integrating into assembly lines.

Constructed from durable SUS304 stainless steel, the flip air drying machine not only meets stringent food safety standards but also guarantees long-lasting performance in demanding environments. The high-efficiency mesh belt system ensures smooth material transport, while variable frequency control allows operators to customize the speed according to production requirements. With a focus on hygienic operation and energy efficiency, this machine significantly reduces pre-packaging work time, effectively positioning itself as an indispensable asset for businesses aiming to enhance automation and improve overall productivity.

Videos

Features

- One-button operation simplifies learning; includes safety stop.

- Powerful airflow ensures effective drying process efficiency.

- Tailor speed to meet specific product requirements.

- Even drying achieved by exposing materials to airflow.

- Increased air pressure enhances drying performance significantly.

- Set parameters automatically for specific process needs.

- User-friendly controls for different operational area fans.

- Long-lasting design allows for easy maintenance cleaning.

- Reduces manual labor while boosting operational efficiency.

- Stable structure prevents damage during material handling.

- Facilitates easy connection with adjacent equipment installation.

- Collects water, oil, and impurities for efficient cleaning.

- Simplifies collection of wastewater and easy disposal.

- Significantly improves overall production line efficiency consistently.

- Safe and hygienic; complies with food safety standards.

Specifications

| Model | ACDM-4000 |

| Belt Width(mm) | 800/Customized |

| Machine Dimension(mm) | 4000x1100x1400/Customized |

| Voltage(V) | 110/240/380/415/Customized |

| Transfer Motor Power (Kw) | 0.55/Customized |

| Fan Power(Kw) | 0.75*8/Customized) |

| Flip Type(Optional) | Flip/Parallel |

| Conveying Method | Continuous Chain Conveyor Belt |

| Air Drying Method | Conveyor Belt Tilts Forward Air Drying |

FAQ

How to choose one suitable air cooling drying machine?

When selecting one air cooling drying machine, consider the following factors to ensure you choose the most appropriate option for your applications:

Product Type: Identify the type of products you will be drying. The air dryer must accommodate various items, including:

Vacuum-packed products

Bagged products

Canned products

Bottled products

Green leafy vegetables

Fruits

Meat

Mushrooms

Astragalus

Other agricultural products

If you are handling delicate items, such as leafy greens and fragile fruits, a parallel air dryer is suitable as it gently processes these products without risking damage. For soft-packaged meats and sturdier fruits and vegetables, a flip air dryer is recommended due to its robust drying mechanism.

Production Volume: Consider the volume of products you need to dry. Ensure that the air dryer’s capacity matches your production requirements. High-volume operations may require larger machines or multiple units to maintain efficiency.

Space and Setup: Assess the available space in your facility and choose a dryer that fits comfortably. Additionally, consider installation requirements and how well the machine will integrate with your existing processes.

By taking these factors into account, you can select an air drying machine that meets your specific needs and enhances your operational efficiency.

What is the application of flip air drying machine in vegetable, fruit, and meat packaged products, including fried snacks nuggets patties?

Air dryers are vital in the production and processing of various food products, enhancing their quality, shelf life, and convenience. Here’s a breakdown of their applications across three distinct categories: Vegetables and Fruits, Meat Packaged Products, and Snacks.

-Vegetable and Fruit Applications:

Moisture Reduction: Air dryers significantly lower moisture content in vegetables and fruits, preventing spoilage and extending shelf life.

Quality Preservation: The drying process retains the color, flavor, and nutritional value of produce, ensuring high-quality products for consumers.

Convenient Ingredients: Air-dried vegetables and fruits serve as versatile ingredients for various food applications, such as soups, salads, and trail mixes.

-Meat Packaged Products:

Safety Enhancement: By reducing moisture levels in meats, air dryers inhibit microbial growth, improving food safety and extending shelf life, particularly in products like jerky.

Flavor and Texture Improvement: Drying intensifies the natural flavors of meat, creating products with desirable chewiness and taste that appeal to consumers.

Ready-to-Eat Convenience: Air-dried meat products are lightweight and easy to package, making them ideal for on-the-go consumption and appealing to modern snack preferences.

-Fried Snack Nuggets Products:

Healthy Alternatives-Air-dried snacks, such as vegetable crisps and dried fruits, provide nutritious options that align with consumer trends toward healthier eating.

Enhanced Shelf Stability-The air drying process increases the shelf life of snacks, reducing waste and allowing for longer storage and distribution.

Reduce Energy Consumption-Cooling and lowering the temperature facilitates subsequent packaging, freezing and storage, thereby reducing energy consumption in quick-freezing cabinets and quick-freezing tunnel.

Overall, air dryers play an essential role in processing vegetables, fruits, and meats, fostering innovation in packaged products, and meeting the growing demand for convenient and healthy food choices.

What is the operation process of the flip air drying machine?

The operation process of the air dryer involves the following steps:

First, turn on the power to start the fan and conveyor belt.

Next, place the materials to be air-dried evenly at the feed end.

Adjust the conveying speed and fan height based on the characteristics of the material.

Finally, observe the drying process and make adjustments as necessary.

What should be paid attention to in the maintenance of the flip air drying machine?

To maintain your air dryer effectively, consider the following:

Regularly clean the filter and the surface of the equipment to ensure cleanliness and hygiene.

Check electrical connections and transmission parts to guarantee normal operation.

Lubricate the transmission components periodically to extend the machine’s service life.

What are the safety precautions for using the flip air drying machine?

When operating the air drying machine, follow these safety precautions:

Carefully read the operation manual to understand the equipment’s functions and methods of operation.

Do not place your hands in the air drying area while the equipment is running.

Regularly inspect the safety devices of the equipment to ensure they are functioning properly.

If you detect any issues with the equipment, stop the machine immediately for inspection.

INTERESTING? REACH US TO GET Flip Air Drying Machine PRICE NOW!

Related products

Get A Quote Today!

Pages

Archives

- April 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- January 2024

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- August 2022

- July 2022

- June 2022

- June 2018

- May 2018

- April 2018

- March 2018

Categories

- Brine Injector (1)

- Dough Mixer (1)

- Forming Machine (1)

- Sausage Smokehouse (1)

- Uncategorized (166)