Industrial Continuous Fryer

Main Benefits

- Suitable for abundant food frying

- Lower investment with high ROI

- Full stainless steel 304 machine body, accordance with hygiene standards

- Waterproof design, good sealing, easy to clean

- Automatic discharging, 1 Operator needed only

- Steeples speed regulation, controllable frying time.

- Fully automatic and precise temperature control

- Automatic discharging/feeding, easy to operate

- Imported electrical components, ensure machine quality

- Multiple safety devices and alarms, more user-friendly.

- Runs smoothly working without noise

- Timing automatic temperature control system, solve the problem of excessive acidification of fried food.

- Compared with ordinary frying pots, saves 50% of cooking oil.

- Continuous frying production with high output

- Automatic slag removal, equipped with circulating filter system

- Automatically replenish oil to avoid over fried burnt.

Overview

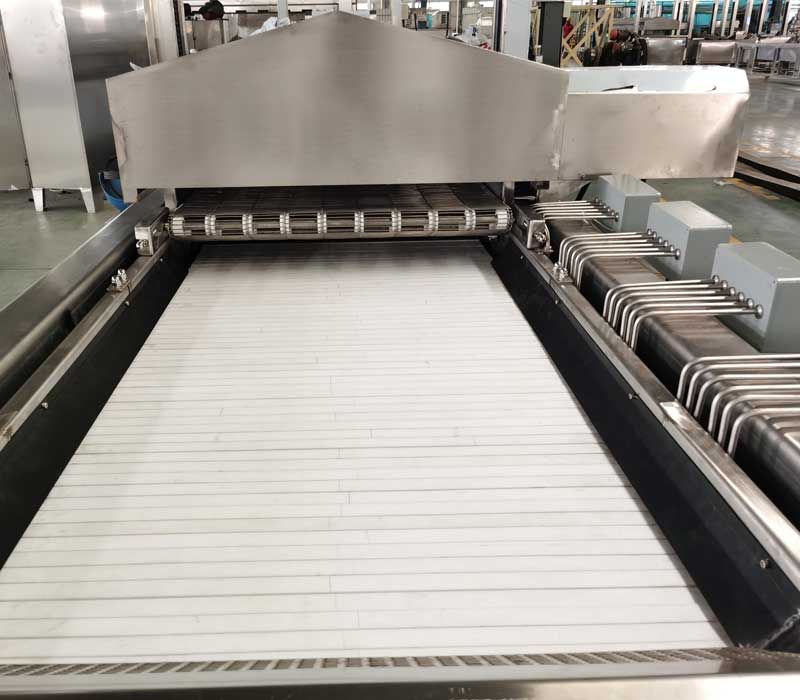

Industrial Continuous Fryer

The industrial continuous fryer adopts unique heating technology to effectively reduce fuel consumption. It is equipped with a user-friendly operation interface and multiple safety device alarms to protect the safety of operators and prolong the service life of the machine. In addition, the fryer adopts a two-layer conveyor belt design, which allows the food to be fully immersed in the oil, cooks evenly, and makes the product even colored.

This industrial continuous fryer not only saves space and energy, but also has a machine self-cleaning system. A hygienic environment for the production of high-quality food is maintained, while the continuous fryer’s multiple heating zones provide optimal temperature control for a consistent, uniform product, and low oil levels produce fresh, crispy food with a long shelf life while accurately control the frying temperature, suitable for frying potato chips, banana chips, mung bean flour, corn sticks, rice crackers, shredded fish, dim sum, chicken legs, pork chops, tofu and dumplings.

Videos

Features

Industrial Continuous FryerThe industrial continuous fryer adopts unique heating technology to effectively reduce fuel consumption. It is equipped with a user-friendly operation interface and multiple safety device alarms to protect the safety of operators and prolong the service life of the machine. In addition, the fryer adopts a two-layer conveyor belt design, which allows the food to be fully immersed in the oil, cooks evenly, and makes the product even colored.This industrial continuous fryer not only saves space and energy, but also has a machine self-cleaning system. A hygienic environment for the production of high-quality food is maintained, while the continuous fryer’s multiple heating zones provide optimal temperature control for a consistent, uniform product, and low oil levels produce fresh, crispy food with a long shelf life while accurately control the frying temperature, suitable for frying potato chips, banana chips, mung bean flour, corn sticks, rice crackers, shredded fish, dim sum, chicken legs, pork chops, tofu and dumplings.

Specifications

| Model | CF-2500 | CF-3500 | CF-4500 | CF-6500 | CF-8500 |

| Capacity(Kgs/hour) | 200-300 | 400-600 | 600-800 | 800-1000 | 1000-1500 |

| Mesh Belt Width(mm) | 300 | 400 | 600 | 600 | 800 |

| Heating Source | Electric / Gas | ||||

| Temperature Range(℃) | 0-230 | ||||

| Overall Dimension(mm) | 2700*800*1400 | 4500*1600*2000 | 6000*1600*2400 | 6500*2000*2000 | 8500*2200*2000 |

FAQ

Why should I order one french fries continuous frying machine?

Frying is a common process in food manufacturing and a very popular food preparation method today. So far, after a long history of food processing, there are a wide variety of fried foods, such as potato chips, doughnuts, french fries, fried twist, chicken legs, fried fish products, potato chips, etc. Under the huge demand for fried food in the international market, there should be efficient and safe fried food production equipment.

This french fries continuous frying machine is a large-scale food processing equipment that can make fried food on a large scale. The frying tank inside the machine can be lifted for deep cleaning to ensure the cleanliness of the entire frying process. The machine can produce and process the following products:

1. Pasta; Dough, rice, fried dough sticks, caramel snacks, etc.

2. Meat: Colonel chicken nuggets, meat patties, braised pork, meatballs, beef jerky, fatty meat, chicken, pork trotters, chicken chops.

3. Nuts: peanuts, beans, broad beans, sunflower seeds, chickpeas;

4. Seafood; fish, shrimp, squid rings.

5. Others: vegetables, puffed food, potato chips

With a continuous fryer, you can not only fry products faster and save labor, but also produce more brighter color nugget and save more oil.

How to operate the french fries continuous frying machine?

– When using this fryer, the oil should be preheated for about 20 minutes before adding the ingredients.

– When the temperature reaches about 150 degree, the frying material can be added via a conveyor belt ( coating equipment is usually connected to the continuous fryer).

– Food is fed into boiling oil through its internal mesh belt conveyor for frying and then discharged from the machine outlet. Actual frying time will be various depending on the processed food.

How to clean the french fries continuous frying machine?

-After using, be sure to unplug the fryer and start cleaning after the fryer is completely cooled.

-When cleaning, use a soft cloth soaked in neutral detergent to wipe gently.

-Do not use metal brushes, corrosive solvents, etc, to avoid damaging the non-stick coating and the pot body. surface.

-Do not put the entire continuous fryer in water for cleaning to avoid electric shock hazards and malfunctions. The attached debris can be wiped off with a wrung, damp cloth.

-The detachable inner pot oil net can be cleaned with a soft cloth dipped in water and detergent.

-When not in use for a long time, please clean the electric heating fryer and store it after drying.

Does this french fries continuous frying machine save oil?

-Equipped with an automatic filtering system, this continuous frying machine could keep the frying oil clean and make the fried products consistent, which not only improves the product quality, prolongs the shelf life, but also brings higher added value to the products.

-Automatic filtration can greatly extend the service life of frying oil, without frequent oil change.

-The oil consumed during the frying process of the product is equivalent to the oil absorbed by the product, and the fuel-saving efficiency very high.

-The advanced heating system avoids energy waste to a greater extent and saves a lot of energy expenditure.

-The realization of the continuous work of the machine improves the working efficiency, effectively reduces the unit cost for the product.

What is your guarantee of this french fries continuous frying machine?

-We provide 12 month warranty time once delivery for full machine.

-We will send you all detail operation videos, including how to operate, clean,etc. Any questions will be well solved.

-All machine will be well tested before delivery. Our after sale service team will reply you 7*24 hours, online technical support available all the life time.

-What is more, our engineers are also available overseas if needed. Please never worry about after sale service, it is a very easy operation machine.

INTERESTING? REACH US TO GET Industrial Continuous Fryer PRICE NOW!

Related products

- Continuous Frying Machine

Commercial Continuous Fryer

Commercial continuous fryer with 150-200kg capacity, 304 stainless steel, automated 3-layer mesh belt for even frying of fries, donuts, and chips.

Product overview - Continuous Frying Machine

French Fries Continuous Frying Machine

Equipped with an oil-water mixing process, this french fries continuous frying machine could decrease the waste residue generated in the process of frying food sinking into the oil, at any time, and the oil in the residue returns to the oil layer, and the food residue is excluded.

Product overview - Continuous Frying Machine

Chicken Patty Nuggets Frying Machine

Using digital temperature control, the frying temperature could reach max 300 degrees, with high-temperature upper limit power-off function designed, while the temperature exceeds the set temperature and the power is cut off, creating a safe and quiet working environment for operators.

Product overview

Get A Quote Today!

Pages

Archives

- April 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- January 2024

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- August 2022

- July 2022

- June 2022

- June 2018

- May 2018

- April 2018

- March 2018

Categories

- Brine Injector (1)

- Dough Mixer (1)

- Forming Machine (1)

- Sausage Smokehouse (1)

- Uncategorized (169)