Tabletop Fish Skinning Machine

Main Benefits

- Suitable for various fish processing needs

- Achieves 98% peeling cleanliness

- Compact design, occupies minimal space

- No pressure on fillet, preventing damage

- Handles thawed, and fresh fillets

- Hygienic design for easy cleaning

- High efficiency, replaces 30-50 workers

- Quick return on equipment investment

- Easy to disassemble for thorough cleaning

- User-friendly operation and maintenance

- Powerful motor for consistent performance

Overview

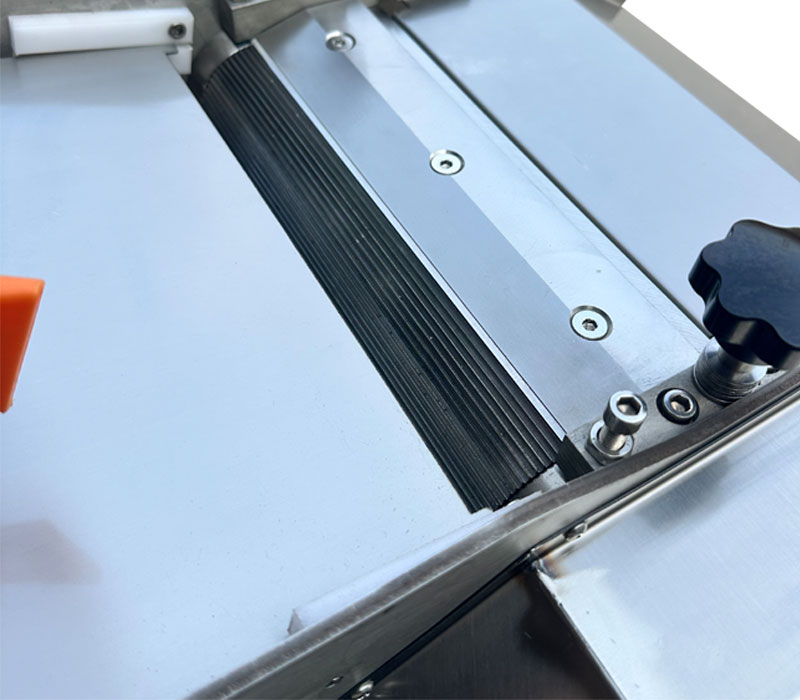

VERFOODSOLUTIONS presents an advanced range of tabletop fish skinning machines, engineered to deliver exceptional results across a diverse spectrum of freshwater and saltwater species. This state-of-the-art tabletop fish fillet skinning machines excel in removing skin from numerous common species, including flounder, cod, sole, catfish, tilapia, and squid. Crafted entirely from 304 stainless steel, our tabletop fish fillet skinning machine boast a hygienic, ergonomic design with fully welded joints and rounded corners, preventing moisture and dirt penetration. The gentle yet effective skinning process handles fillets of all sizes without applying damaging pressure, achieving an impressive 99% skinning rate with minimal product loss.

To maximize your yield and streamline processing operations, VERFOODSOLUTIONS tabletop fish skinning machines incorporate user-friendly interfaces and tool less assembly/disassembly features, making operation and maintenance effortless. Safety is paramount, with vandal-proof and auto-cut safety switches, alongside splash-proof casings for electrical components. The powerful motor, coupled with imported, sharp, non-stick quality blades, consistently delivers 98% peeling cleanliness. Operators can easily adjust fillet thickness and customize discharge baffles to suit various processing needs. The compact design occupies minimal space while offering maximum efficiency, potentially replacing 30-50 workers and ensuring a quick return on investment. To get the best out of your fillets and stay ahead in the competitive seafood processing industry, consult our fish skinning specialists who will guide you to the perfect VERFOODSOLUTIONS skinning solution tailored to your individual application.

Videos

Features

- Easy tool less regulation with preset basic settings

- Hygienic, ergonomic design featuring rounded corners

- Blade replacement requires no tools

- Electrical components housed in splash-proof casing

- Vandal-proof and auto-cut safety switches for enhanced security

- Fully welded joints prevent moisture and dirt penetration

- Universal water spray faucet for flexible cleaning

- Sharp steel blades ensure accurate, time-saving fish fillet cutting

- Adjustable fish fillet thickness for versatile processing

- Efficient high-pressure fish meat wheel for convenient processing

- Durable stainless steel roller for long-lasting performance

- Quick and efficient fish fillet cutting with fine steel blades

Specifications

| Model | FSM-300 | FSM-400 |

| Capacity(Pcs/min) | 15-30 | 30-50 |

| Voltage(V) | 110/220/240/380/415 | 110/220/240/380/415 |

| Roller Speed(m/min) | 14 | 22 |

| Power(Kw) | 0.2 | 0.75 |

| Weight(Kgs) | 48 | 98 |

| Dimension(mm) | 540*420*410 | 650*570*900 |

FAQ

Why should I order one unit tabletop fish skinning machine?

Investing in a VERFOODSOLUTIONS tabletop fish skinning machine can revolutionize your seafood processing operations. This advanced equipment significantly increases efficiency by replacing 30-50 workers, dramatically reducing labor costs while maintaining consistent, high-quality results with a 98-99% peeling cleanliness rate. The machine’s versatility allows it to handle a wide range of freshwater and saltwater species, adapting to various fillet sizes and conditions. Its gentle skinning process maximizes yield by preserving valuable fillet meat, ensuring higher profits. Constructed from 304 stainless steel, the machine meets strict hygiene standards, while its user-friendly design with toolless disassembly simplifies operation and maintenance. The compact, space-efficient design offers maximum output in minimal floor space. With customizable features, comprehensive safety measures, and the potential for quick return on investment, a VERFOODSOLUTIONS fish skinning machine is not just equipment, but a strategic investment in your company’s future in the competitive seafood processing industry.

What is the application for tabletop fish skinning machine?

The tabletop fish skinning machine is a versatile tool designed for the efficient removal of skin from a wide variety of fish species. It can process both saltwater and freshwater fish, including flatfish, round fish, and even some non-fish seafood. The machine is capable of skinning various kinds of fish, as well as some whole fish depending on the species and size.

It’s suitable for

- Flatfish: flounder, halibut, plaice, sole, skate, turbot

- Round fish: alaska pollak, bream, carp, cod, catfish, grouper, herring, hake, mahi-mahi, mackerel, perch, pike, salmon, snapper, tilapia, ling, whiting, pangasius-basa, tuna, nile perch, haddock

- Other seafood: ray, shark, squid, monkfish, cuttlefish, dogfish

The machine can handle both delicate species and those with thick, scaled skin. It performs regular skinning and deep-skin applications (with an optional tool), and can operate with or without water on the fillets. This versatility makes it suitable for various processing environments and requirements in the seafood industry.

Is the tabletop fish skinning machine safe to operate?

The VERFOODSOLUTIONS tabletop fish skinning machine is engineered with operator safety as a paramount concern. Our machine incorporates a comprehensive array of safety features to ensure secure operation. These include vandal-proof and auto-cut safety switches, splash-proof casings for electrical components, and a waterproof one-button switch for reliable control. The ergonomic design with rounded corners minimizes injury risks during operation and cleaning. Safe handling of fish fillets is ensured through infeed and outfeed conveyors. The machine’s toolless assembly/disassembly system for components like the skinning shoe and blades reduces accidents during maintenance. Additionally, the hygienic design with fully welded joints prevents contamination risks. The machine’s stability during operation ensures high accuracy and further enhances safety. With a user-friendly interface, preset settings, and comprehensive training provided, operators can confidently use the machine. These features, combined with proper adherence to operating instructions, make our fish skinning machine a safe and dependable choice for all seafood processing operations.

What is your initial setup and safety checklist for your tabletop fish skinning machine?

When you first receive your tabletop fish skinning machine, there are several crucial steps to ensure proper setup and safe operation:

1. Placement: Position the machine on a flat, solid surface to ensure stability during operation.

2. Bolt inspection: Thoroughly check the tightness of all bolts and connections. Retighten any loose parts to prevent malfunction or safety hazards.

3. Wear part examination: Inspect all wearing parts for any damage that may have occurred during shipping. Replace any damaged components according to specified requirements.

4. Safety check: Ensure all safety protection devices are properly installed before attempting to start the machine. Never operate the equipment if any defects are detected.

5. Electrical safety: Carefully examine all electrical connections and wiring for signs of damage or potential leakage. Do not proceed with setup if any electrical issues are found.

6. Power requirements: Verify that your power supply matches the machine’s specifications. Using an incompatible power source can damage the equipment and pose safety risks.

By diligently following these steps, you’ll ensure your new fish skinning machine is set up correctly, operates safely, and performs at its optimal level from the start.

How do I ensure safe operation of the tabletop fish skinning machine?

A: To ensure safe operation of the fish skinning machine:

- Set up in a spacious, ventilated, and fireproof area.

- Dress appropriately: tie up long hair and wear neat clothing.

- Keep the power switch easily accessible.

- Always turn off the power before inspecting or maintaining the machine.

- Regularly check for damaged components and repair or replace them promptly.

- Never operate the machine with known defects.

- Periodically tighten bolts on all transmission components.

- Feed fish continuously and evenly, maintaining a moderate feeding amount.

- Avoid introducing hard debris into the machine.

- Use high-quality, imported knives suitable for various fish peeling operations.

By following these precautions, you can maintain safety, efficiency, and quality in your fish skinning operations.