Vegetable Dehydrator Machine

Main Benefits

- Versatile use for various food products and materials.

- Environmentally friendly with no waste generation during drying.

- Preserves nutritional content of food during drying process.

- Quiet operation improves working environment and comfort.

- Adjustable convection for even temperature distribution throughout chamber.

- Automatic control optimizes temperature and humidity levels.

- Energy-efficient drying saves electricity and reduces operational costs.

- Fully automatic control reduces labor and effort.

- High air flow enhances hot air circulation efficiency.

- Maintains bright color and quality of finished products.

- Long service life and low operating costs enhance efficiency.

- Extends shelf life, preventing spoilage of dried goods.

- Smooth operation simplifies installation and maintenance tasks.

- Durable construction ensures long-lasting performance and reliability.

- Meets food hygiene requirements for safe processing.

Overview

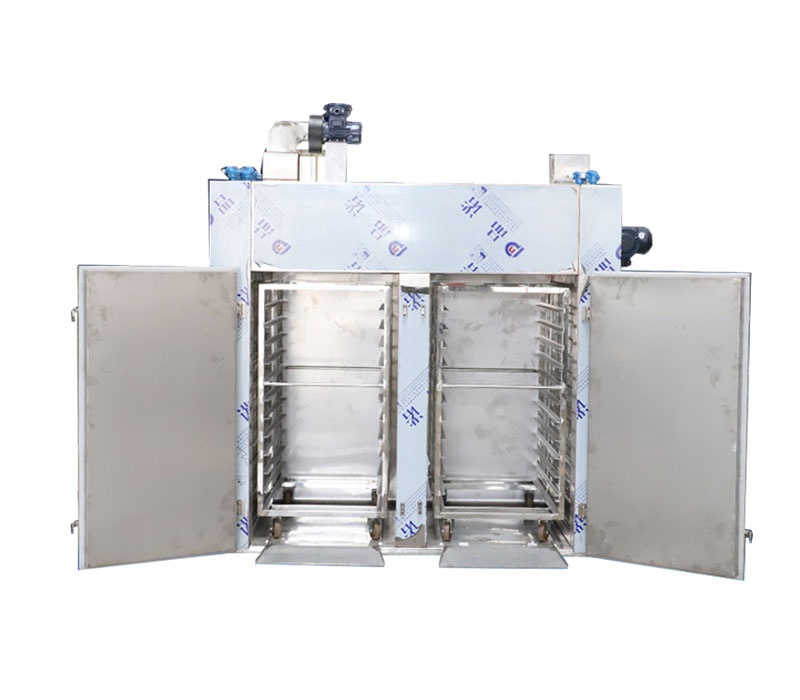

Enhance your vegetable preservation techniques with our cutting-edge vegetable dehydrator machine, specifically designed for effective dehydration while efficiently retaining nutritional value. This innovative equipment allows operators to select the appropriate hot-air circulation mode based on the product layout, ensuring uniform temperatures throughout the furnace for remarkable drying effects. Ideally suited for a variety of vegetables—such as carrots, bell peppers, zucchini, and green beans—it promotes uniform drying that preserves the fresh color and essential nutrients of your produce. Constructed from SUS304 stainless steel, the robust drying chamber is fully welded and mirror-polished, resulting in a compact design that is both visually appealing and easy to clean, requiring minimal maintenance.

The integrated design features adjustable air distribution plates to ensure even hot air circulation throughout the dehydrating chamber, effectively eliminating any hot or cold spots during the drying process with a temperature difference of less than ±1°C across the chamber. High-quality thermal insulated aluminum silicate cotton minimizes thermal conductivity and employs a unique heat preservation method that enhances insulation performance while promoting energy savings. With advanced electrical controls and an intelligent program temperature controller, operators can set up curing curves according to various processing needs, simplifying operation without sacrificing performance reliability. Designed for both small-scale farms and large processing plants, this vegetable dehydrator machine is an essential investment that significantly improves productivity and product quality while ensuring that nutrients and vibrant colors are maintained for enhanced culinary applications.

Videos

Features

- Customization heating includes thermal oil, steam, hot water, electricity, and infrared.

- Control options feature touch screen and traditional panel for easy use.

- High energy efficiency maximizes hot air circulation within an insulated chamber.

- Adjustable plates optimize airflow for even drying and forced ventilation.

- Automatic control maintains ideal temperature without manual adjustments needed.

- Quick recovery ensures targeted temperatures are reached efficiently.

- Inlet features primary and medium efficiency filters for customized air quality.

- Intelligent thermostat self-tunes for precise temperature control during drying.

- Excellent insulation reduces energy consumption and operating costs significantly.

- User-friendly controls enable straightforward temperature and airflow settings.

- Air distributor ensures consistent hot air distribution for reliable drying.

- Various tray types let you process a range of wet materials.

- Eco-friendly design operates without harmful emissions, reducing pollution.

- Hygienic construction from SUS304 stainless steel allows for easy cleaning.

Specifications

| Model | Heating Way | Batch Capacity (Kg) | Tray Size (mm) | Tray No. | Trolley Size(mm) | Trolley (Set) | Machine Dimension L*W*H(mm) |

| FDM-10CT | Electric/Steam/Natural Gas/Thermal Oil | 120-160 | 600*800 | 24 | 1200*800*1800 | 1 | 2000* 900*1950 |

| FDM-20CT | Electric/Steam/Natural Gas/Thermal Oil | 240-288 | 600*800 | 48 | 1200*800*1800 | 2 | 3000*1200*2000 |

| FDM-30CT | Electric/Steam/Natural Gas/Thermal Oil | 480-576 | 600*800 | 96 | 1200*800*1800 | 4 | 3000*2200*2000 |

| FDM-40CT | Electric/Steam/Natural Gas/Thermal Oil | 720-864 | 600*800 | 144 | 1200*800*1800 | 6 | 4400* 2200*2600 |

| FDM-50CT | Electric/Steam/Natural Gas/Thermal Oil | 960-1152 | 600*800 | 192 | 1200*800*1800 | 8 | 5600* 2000*2600 |

| FDM-60CT | Electric/Steam/Natural Gas/Thermal Oil | 1200-1440 | 600*800 | 240 | 1200*800*1800 | 10 | 6800*2400*2700 |

Note:

Above parameters are for standard models, it can be customized according to customers requirements.

① Effective heating temperature 30-180℃.

② Tray size also can be 600*460, we can customize.

③ Machine material can be aluminum plate or stainless steel.

FAQ

What should I confirm before purchasing one vegetable dehydrator machine?

Before purchasing one vegetable dehydrator machine, it’s essential to confirm the following questions.

Heating Method: Determine the type of heating method that best suits your needs, such as electric, natural gas, coal, or steam, thermal oil .

Product Specifications: Identify the types of products you will be drying and their approximate sizes to ensure the dryer can accommodate them.

Weight and Output: Assess the product weight, including single weight and the desired hourly output to align with your production requirements.

Moisture Content: Understand the initial moisture content of your products before drying and establish the target moisture requirements after drying to ensure optimal performance.

By confirming these parameters, you can select the right dehydrator machine that meets your specific needs.

What are the primary uses of vegetable dehydrator machine?

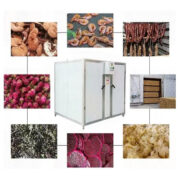

Food dehydrator machines are primarily used for drying a wide range of products to enhance their economic value and increase earnings. Key applications include:

Agricultural Products: Dehydrator machines are used for fruits (like jujube, lychee, and longan), vegetables (such as peppers and edible fungi), and grains (including rice and corn) to prolong shelf life and improve preservation.

Meat Products: The dehydrator machine helps in drying various meats, including beef jerky and cured meats, which removes moisture and helps in preservation while extending their shelf life.

Seafood: Drying seafood such as fish, shrimp, and squid not only preserves these products but also enhances their flavor and texture.

Medicinal Materials: Drying Chinese medicinal herbs like honeysuckle, ginseng, and star anise is crucial for maintaining their potency and shelf life.

Dried Flowers & Forage: Flowers (like roses and chrysanthemums) and forage are dried to retain their properties for use in various applications.

Industrial Uses: Dryers are also employed in industrial applications for drying chemical products, sludge, paper products, and other materials.

Overall, the drying process helps in moisture evaporation, thereby ensuring preservation, preventing spoilage, and extending the usability of various products across different industries.

How to dehydrating mushroom with VERFOODSOLUTIONS vegetable dehydrator machine?

The shiitake mushrooms can only be dried when the temperature in the drying room rises to 35℃. Two wet-bulb thermometers should be hung near the windows in the room. When drying, the temperature must be low first and then gradually increased. Usually, the temperature increases by 1-3℃ per hour, and the maximum temperature should be controlled at 80-85℃. It is generally required to bake at 35-40℃ for 6 hours → bake at 40-60℃ for 8-10 hours → bake at 60℃ for 2 hours.

The higher the moisture content of shiitake mushrooms, the longer it needs to be baked at low temperatures. If the temperature rises suddenly at the beginning of baking, it will inevitably cause the tissue to lose water too quickly, which will easily cause the shiitake mushroom cap to deform and become irregular, the gills to overlap, the cap to crack, the color to turn black, and the activity of the enzyme to be destroyed, so that the shiitake mushrooms lose their original fragrance. After the shiitake mushrooms are sent to the drying room, they should be baked continuously until they are dry. The heating cannot be interrupted, and the temperature cannot fluctuate, otherwise, the color of the shiitake mushrooms will turn black and the quality will decrease.

Dehumidification In the process of baking shiitake mushrooms, in addition to strictly controlling the heating temperature, timely dehumidification is also an important link. Dehumidification holes must be set on the upper part of the drying room. The general principle of dehumidification is: in the early stage of baking shiitake mushrooms when the temperature of the drying room is 35-40℃, all dehumidification holes or exhaust fans should be opened; when the temperature rises to 40-60℃, dehumidification for 3-4 hours is sufficient. After 60℃, all dehumidification holes can be closed and dehumidification is not required. Excessive dehumidification can easily make the shiitake mushrooms pale white. If the baked shiitake mushrooms have a water-soaked yellow color, it means that the dehumidification is not good, or the furnace temperature is not enough, especially when the heat is stopped in the middle, it is more likely to cause this phenomenon.

When baking for 16-18 hours, the door of the drying room can be opened to check whether the dryness of the shiitake mushrooms is qualified. When checking, press the junction of the cap and the stem with your fingers. If only traces are present, it means that the drying is qualified; if it feels soft and the gills are also soft, it is necessary to continue drying. The characteristics of qualified dried products are: they have the special fragrance of shiitake mushrooms; the gills are yellow, upright, complete, and not falling; the water content of the mushroom body does not exceed 13%; the shiitake mushrooms maintain their original shape, the cap is round and flat, and the natural color is maintained.

What are the general dehydrating processes for various products like dates, mushrooms, sweet potatoes, and flowers/herbal medicine?

The dehydrating processes for these products vary slightly in temperature and time, but generally follow structured guidelines to ensure quality:

Date Dehydrating:

Process:

Start at 45-50°C with 50% humidity.

Increase to 68-70°C with good ventilation and dehumidification.

Final baking at 55-70°C for 15-20 hours until moisture content reaches 15%.

Note: Allow cooling before stacking to prevent fermentation.

Mushroom Dehydrating:

Parameters:

Bake at 35-40°C for 6 hours.

Increase to 40-60°C for 8-10 hours.

Finish at 60°C for 2 hours.

Dehumidification:

Open holes fully at 35-40°C.

Dehumidify for 3-4 hours at 40-60°C.

Close dehumidification after reaching 60°C.

Sweet Potato Dehydrating:

Parameters:

Bake at 65°C for 15-18 hours (humidity 10%).

Expect about 25kg of dry product from 100kg of fresh potatoes.

Note: Timing may be adjusted based on moisture content and cargo volume.

Flower/Herbal Medicine Dehydrating:

Parameters:

Dry at 25-35°C for 3-4 hours.

Increase to 55-65°C for 18-19 hours until moisture content is 8-12%.

Note: Spread in layers of 8-10 cm thick, then cool to 40°C before transfer.

By following these guidelines, optimal quality and preservation of these products can be achieved during the drying process.