Beef Pork Chicken Breast Horizontal Slicer

Main Benefits

- Adjust belt height automatically to fit for different thickness of meat

- Great cutting precision compared to manual work

- High throughput without waste

- Hygienic production process

- Efficient, safe operation and easy maintenance

- Stainless steel material and engineer plastic makes it waterproof

- Saves labor cost, easily handle by one operator

Overview

Beef Pork Chicken Breast Horizontal Slicer features a double floating belt design, cutting various meats for continuous production with VERFOODSOLUTIONS

Videos

Features

- Suitable for big size beef, pork back meat, tenderloin, thick chicken breast horizontal slicing works

- Safety switch equipped on the cover. Stainless steel and non-metallic materials in conformity with FDA standard

- Pneumatically lifting is adopted for compacting the conveyor belt. Easy operation and convenient maintenance

- Adjustable cutting thickness, high efficiency & cutting accuracy

- Recommended for boneless and fresh meat cutting

- The conveyor belt is driven by drum motor, safe and reliable

- Made in stainless steel and other non-corrosive materials

- HACCP and CE authorization

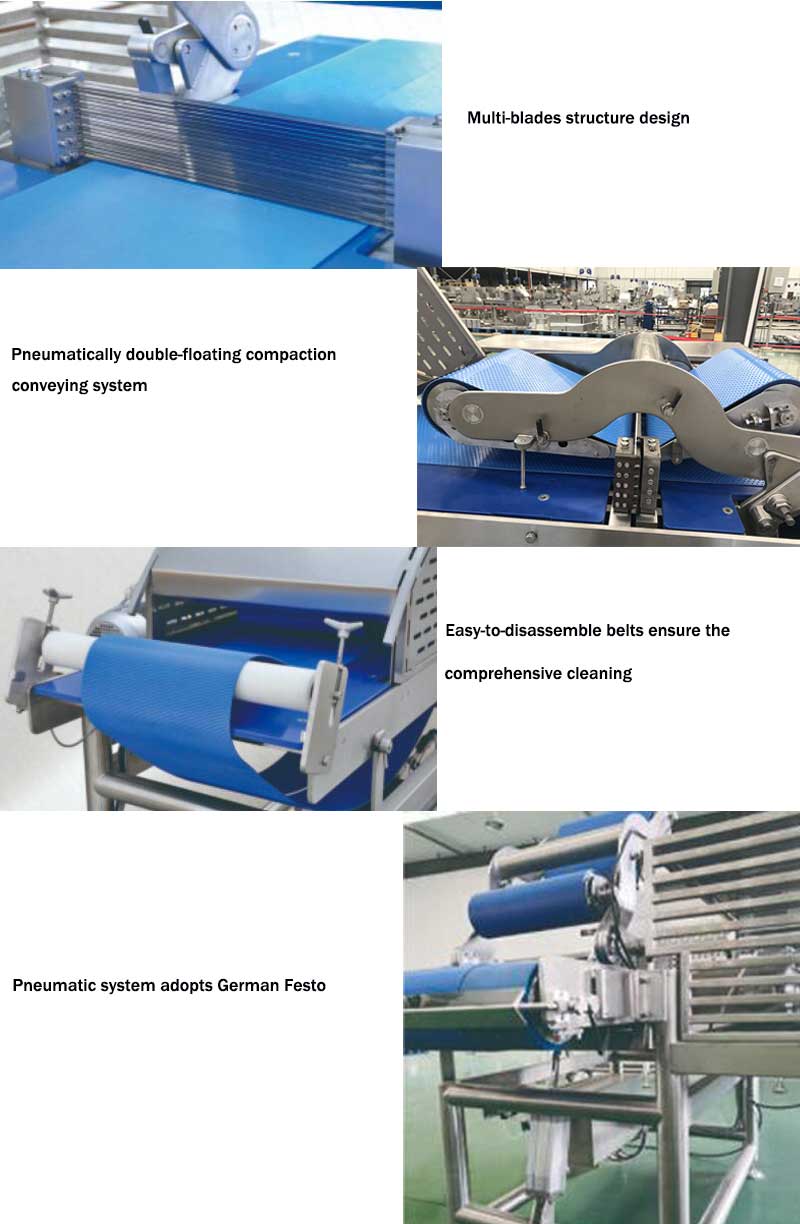

1.Special multi-blades structure design can realize all the blades to achieve best slicing satiation and minimize the slicing error.

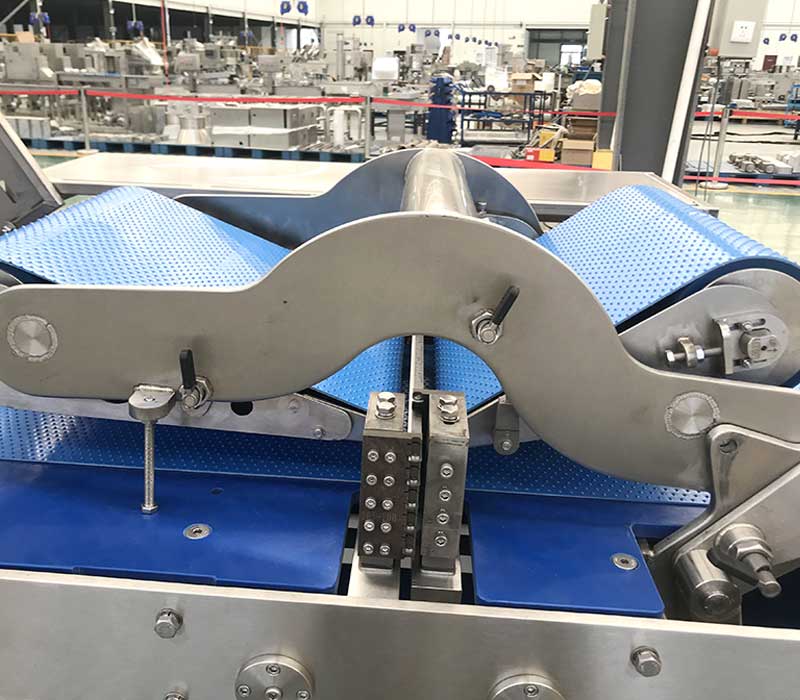

2.Pneumatically double-floating compaction conveying system is adopted, which can be adjusted automatically according to different thickness of raw material.

3.The pneumatic system adopts German Festo brand, which is safe and reliable

4.Easy-to-disassemble belts ensure the comprehensive cleaning, CE approved.

Specifications

- ModelHS380

- Mesh Belt Width(mm)380

- Mesh Belt Speed(m/min)3-15

- Cutting Capacity(Kg/Hour)1000

- Raw Meat Temperature≥-2℃

- Max Cutting Thickness(mm)50

- Cutting Thickness(mm)≥4

- Input&Output Height(mm)1050±50

- Power(Kw)2.0

- Dimension(mm)2180*1150*1480

FAQ

Why should I order one horizontal slicer?

This beef pork chicken breast horizontal slicer could be widely applied to butcher shops, delis, supermarkets, small good stores, industry, industrial kitchens, the wholesale sector and other meat production settings. Moreover, this slicer can highly increase your working efficiency and reduce the worker stress.

What is the difference between the HS-200 and HS-380 model?

The biggest difference is the HS-380 model adopts new double floating belt conveying design, widely cutting range (the 380mm width × 120mm height). It can meet customers’ requirements for processing different sizes and various shapes of raw meat. And HS-200 model cutting lane width is fixed, can only cut raw meat width as 14cm, and thickness can be only 6cm max., in other words, HS-380 model fit for big sizes meat horizontal slicing.

What is the application of this horizontal meat slicer?

This horizontal slicer machine not only use for cutting fresh meat but also it is helpful in cutting chicken, thin beef, pork, lamb, and other food items and also can process butterflied heart shaped chicken breast fillets.

How to clean the horizontal slicer?

The horizontal slicer is delivered with a cleaning stand for fast and efficient cleaning that meets the continuously increasing hygiene requirements. When cleaning the horizontal slicer, the blade must always be closed and the plug must always be disconnected. Clean with a soft cloth soaked in warm water and mild detergent.

Is it safe to operate this horizontal slicer?

It is absolutely safe from both sides of operation and food standards to use this horizontal meat slicing machine. Full automatic feeding and slicing, equipped with a low voltage control relay, thermal relay and a direction control switch, all these factors could prevent operators from industrial accidents, also guarantee consistent meat quality. Made of full stainless steel and other non-corrosive materials, the machine meets the food industry standards.

What warranty do you offer?

One-year standard warranty applies on horizontal slicer; spare parts will be delivery for free together.