Industrial Contact Cooker

Main Benefits

- Quick cooking for better yield

- Consistent temperature control

- Seals in natural juices and flavors

- Juicy and flavorful results

- Perfectly browned surface

- Uniform color on all surfaces

- No marks on products

- Fat-free cooking for great taste

- Easy cleaning system

- Homemade taste and appearance

- Highly efficient performance

Overview

Introducing the VERFoodSolutions industrial contact cooker, a revolutionary cooking machine that sears and cooks products exclusively in their own fat. This unique cooking method captures the natural flavor of the products, resulting in a delicious and appetizing taste. With the option to create grill stripes and patterns on the products, our contact cooker offers versatility in appearance as well. Operating between an upper and lower PTFE coated belt, the products are cooked by plates that are heated either electrically or by thermal oil. These plates can be customized with grill marks or other patterns, allowing for a desired product appearance. As the products cook in their own fat, there is no need for additional fat, resulting in a healthier and lighter cuisine. Additionally, the efficient cooking method of contact heat ensures minimal weight loss, preserving the quality and integrity of the products.

One of the standout features of our contact cooker is its ability to perfectly process heavily marinated or sticky glazed products. The non-stick abilities of the belt ensure that even the most challenging products can be cooked flawlessly. To maintain hygiene and cleanliness, the non-adhesive Teflon conveyor is equipped with an integrated belt washing system. This system is connected to a Water & Energy Management System, which not only cleans the conveyor but also reduces water and energy usage, cutting costs and minimizing environmental impact. Experience the benefits of our industrial contact cooker and elevate your cooking process to new heights.

Videos

Features

- Adjustable cooking time

- Electric or oil heat source

- Available in 600 or 1000mm width

- Temperature range up to 260°C

- Adjustable plate height for different products

- Utilizes a non-stick Teflon® belt to prevent product sticking

- Cooks without oil for healthier meals

- Adjustable belt height for various products

- Continuous belt-cleaning system

- User-friendly touch screen controls

- Detachable design for easy cleaning

- Made with food-grade materials

Specifications

| Model | CC600 |

| Effective Cooking Width(mm) | 560 |

| Effective Cooking Length(mm) | 1800 |

| Power(Kw) | 61 |

| Belt Width(mm) | 650 |

| Conveyor Belt Speed(m/min ) | 3-15 Adjustable |

| Input Height(mm) | 1050±50 |

| Output Height(mm) | 1050±50 |

| Effective Cooking Height(mm) | 5-50 adjustable |

| Overall dimension(mm) | 3400x1114x1700mm |

| Customized Voltage | 3 Phase 380/415/240V 50/60Hz |

FAQ

Why should I order one contact cooker?

With its sleek design, this contact cooker is both practical and stylish. The contact cooker is perfect for creating delicious meals effortlessly, whether it’s grilled chicken breast filets, mouth-watering patties, or crispy potato pancakes. It gives you authentic grill stripes and roast marks on both sides. Not only that, but our contact cooker can also pre-cook, speeding up the cooking process. It can even create unique grill stripe patterns if desired. The secret lies in its innovative design, cooking the products in their own fat for a natural taste without the need for additional fat. It’s the perfect choice for healthier and lighter cuisine, preserving the natural flavor and minimizing weight loss. With its non-stick abilities, cooking becomes hassle-free.

What kind of product this contact cooker could deal with?

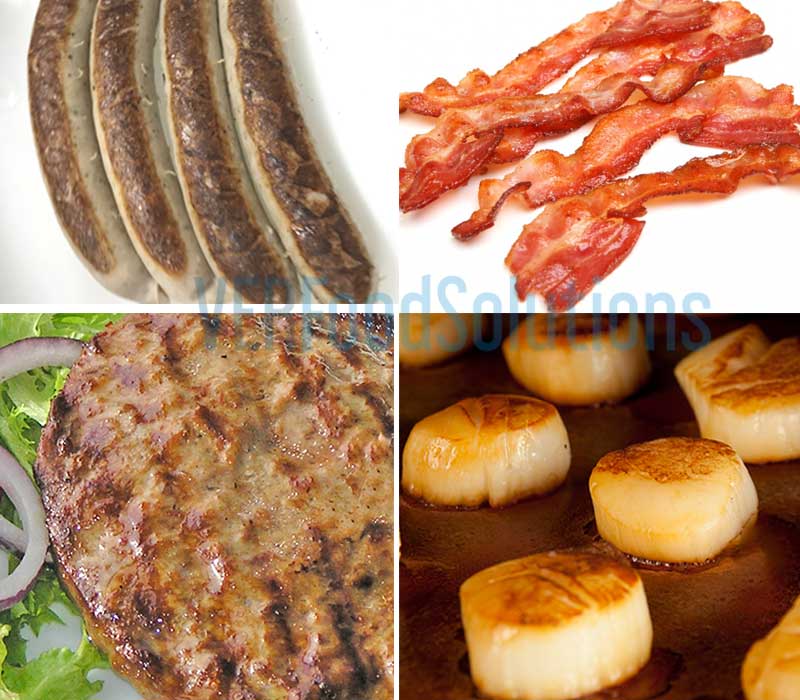

The contact cooker is especially effective for flat, de-boned, whole muscle, minced meat products such as chicken filets, meat patties, steak, bacon, pancakes, fillet of fish, shrimps, and vegetables. It prevents excessive height expansion during cooking, preserving the quality and integrity of the products. It can easily handle goulash, sliced veal, fresh formed meatballs, and bratwurst. You can also use it to cook bacon in slices or dices, as well as “Schupfnudeln” (finger-shaped potato dumplings). If you prefer healthier options, this machine can cook tofu, fish, and rustic slices of vegetables. It is also great for making potato patties, veggie patties, and potato pancakes. Additionally, it can cook schnitzel and poultry in convenient pieces.

How does the contact cooker achieve perfectly grilled stripes or roast marks on various products?

The contact cooker achieves perfectly grilled stripes or roast marks through the principle of continuous cooking between two cooking belts. This ensures even heat distribution and authentic results on both sides of the product. The intensive 260°C conduction heat transfer from the top and bottom surfaces of the cooker is ideal for browning, searing, and Sous Vide products.

How does the contact cooker promote healthier cooking?

The contact cooker cooks products exclusively in their own fat, resulting in a healthier and lighter cuisine. As the products cook in their own fat, there is no need for additional fat. This unique cooking method captures the natural flavor of the products, resulting in a delicious and appetizing taste.

How does the contact cooker ensure easy cleaning and minimize environmental impact?

The contact cooker is designed with a continuous belt-cleaning system and an integrated belt washing system. This system, connected to a Water & Energy Management System, not only cleans the conveyor but also reduces water and energy usage, cutting costs and minimizing environmental impact. The non-adhesive Teflon conveyor and detachable design further contribute to easy cleaning and maintenance.

How to maintain one contact cooker?

To maintain a contact cooker machine, you can follow these steps:

Cleaning: Regularly clean the machine to remove any food particles or residue. Use a damp cloth or sponge with mild detergent to wipe down the surfaces. Avoid using abrasive cleaners or scouring pads that may damage the machine.

Grease management: Check and clean the grease trap or collection tray regularly. Grease buildup can affect the performance of the machine and may pose a fire hazard.

Lubrication: Some contact cooker machines have moving parts that require lubrication. Refer to the manufacturer’s instructions to identify the specific parts that need lubrication and use the recommended lubricant.

Inspection: Periodically inspect the machine for any signs of wear and tear, loose parts, or damage. If you notice any issues, contact a professional technician for repairs or maintenance.

Electrical safety: Ensure that the power cord and plug are in good condition, without any fraying or damage. If you notice any issues, replace the cord or plug immediately to prevent electrical hazards.

Regular servicing: Schedule regular maintenance services with a qualified technician. They can perform thorough inspections, cleanings, and address any potential problems to keep the machine running smoothly.