Industrial Smokehouse

Main Benefits

- User-friendly and hassle-free operation

- Dependable and consistent performance

- Seamless welding technique for durability

- Consistent smoke production for stable results

- Energy-efficient and effective performance

- Zero waste emissions for environmental friendliness

- Maintains cleanliness and hygiene standards

- Robust and durable construction

- Fully automated control with PLC interface

- Flexibility to perform individual or combined processes

- Achieves uniform color in meat products

- Ample storage for 100 unique formulas

Overview

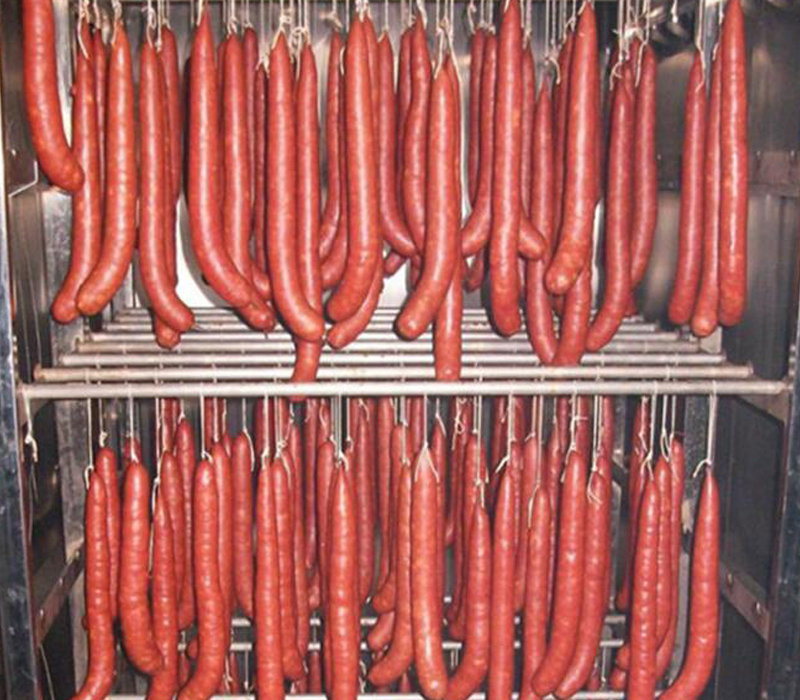

The VERFoodSolutions industrial smokehouse serves as a fundamental apparatus in the maturation process of meat products. It encompasses a wide range of functionalities including cooking, drying, baking, smoking, exhausting, and cleaning. Specifically designed for the processing of meat products such as intestines, smoked chicken, smoked fish, smoked duck, smoked goose, and smoked meat, the oven smoke house excels in its ability to cook, dry, smoke, and enhance the color of the products. Notably, this equipment boasts low power consumption, costing only 60% of the expenses incurred by coal-burning alternatives. By utilizing a smoker, not only can product quality be elevated and hygiene ensured, but it also enables a reduction in production costs. Thus, the oven smoke house serves as an invaluable asset for on-site meat production.

The industrial smokehouse frame’s interlayer is filled with imported high-temperature-resistant polyurethane foam material, resulting in a seamless formation that enhances thermal insulation and exhibits excellent sealing performance. This design feature not only contributes to energy conservation but also improves overall efficiency. Key electrical components of the smoker, including the touch screen, programmable controller, relays, and solenoid valves, are all sourced from reputable international suppliers. The human-machine interface, equipped with a large window, vividly and intuitively displays the equipment’s operational status. During operation, various parameters such as time, temperature, and exhaust air size can be easily adjusted, thanks to the user-friendly interface. The industrial smoker’s operation is remarkably straightforward. Additionally, it boasts an exceptional smoke generation and circulation system, ensuring even distribution of smoke within the furnace. As a result, the meat products are uniformly colored and visually appealing, while simultaneously guaranteeing a high product yield. Suitable for use in large, medium, and small food processing plants, the oven smoke house is an ideal choice for both Chinese and Western meat products, including sausages, hams, dry sausages, roast chickens, roast ducks, and barbecues. Moreover, it is also well-suited for various lunch meats, grilled fish fillets, smoked dried beans, and other related categories.

Videos

Features

- Users could adjust parameters during production process

- PLC control panel sets smoking time and temperature

- Equipped with operator password and production records

- Monitors smoke temperature for safety and hygiene

- Double-layer stainless steel radiator for quick heating

- Double valve cabinet door switch for safer operation

- Control panel has emergency stop button for safety

- Human-machine interface displays equipment’s operating status

- Excellent smoke generation and circulation system for even distribution

- Disc-shaped electric heating tube increases smoking area and speed

- Reasonable air design ensures uniform temperature inside furnace

- Automatic fire extinguishing device and even smoke distribution

- Double-pass double-row smoke generator with controllable smoke box

- Intelligent operating system operates automatically

- Host frame filled with high-quality aluminum silicate felt

- Programmable controller and touch screen display equipment status

- Displays and controls temperature, humidity, and time

- Single or combined processes for flexible production

- Stores hundreds of fixed programs for easy access

Specifications

| Model | Machine Dimension(mm) | Smoking House Size(mm) | Sausage cart dimensions (mm) | Power(Kw) | Capacity (Kg/batch)

| |

Steam Heating (Kw) | Electric Heating (Kw) | |||||

| SH-30 | 1300*1100*1670 | 1000*1100*1440 | 800*715*880 | 2.75 | 15.75 | 30 (50 chickens/batch) |

| SH-50 | 1300*1100*1840 | 1100*1150*1600 | 900*820*1040 | 4.5 | 16.5 | 50 (50 chickens/batch) |

| SH-75 | 1650*1200*2200 | 1350*1200*1700 | 970*1040*1220 | 6 | 18 | 100 (80 chickens/batch) |

| SH-100 | 1700*1300*2400 | 1350*1300*2100 | 900*1000*1500 | 6 | 24 | 150 (100 chickens/batch) |

| SH-150 | 1700*1200*2600 | 1400*1200*2300 | 1000*1000*1750 | 6 | 24 | 200 (130 chickens/batch) |

| SH-250 | 1800*1100*3000 | 1500*1200*2530 | 1050*1050*1970 | 8 | 27 | 250 (200 chickens/batch) |

| SH-500 | 1800*2250*3000 | 1050*1050*1970 | 1050*1050*1970 | 12 | 48 | 500 (450 chickens/batch) |

| SH-1000 | 1800*4400*3000 | 1500*4400*2530 | 1050*1050*1970 | 20 | 90 | 1000 (1000 chickens/batch) |

FAQ

What kind of products this industrial smokehouse could smoke?

The sausage smokehouse is designed to effectively smoke a variety of foods. It is suitable for processing sausages, bacon, dried tofu, chicken, duck, goose, beef jerky, and other similar products. The smoker is versatile and can be used for different categories of food items.

One of the main categories of products that can be processed in the smokehouse oven is soy products. This includes dried tofu and various bean products. The smoker provides an ideal environment for smoking these soy products, enhancing their flavor and texture.

In addition to soy products, the sausage smokehouse is also suitable for processing meat products. This includes sausages, Harbin Red Sausage, bacon, roasted pork, pork head, pork trotters, salmon, smoked duck, smoked chicken, roast chicken, eggs, and quail eggs. The smoker ensures that these meat products are smoked to perfection, resulting in delicious and flavorful dishes.

Another popular product that can be smoked in the smoker is sausage. Whether it’s bacon or regular sausages, the smoker is designed to handle the smoking process effectively. It ensures that the sausages are evenly smoked, enhancing their taste and aroma.

In conclusion, the smoker is a versatile appliance that can be used to smoke a wide range of products. From soy products to meat items and sausages, the smoker ensures that each product is smoked to perfection, resulting in delicious and flavorful dishes.

How to choose a right industrial smokehouse?

When choosing the right smokehouse oven, it is important to consider the different types available. The first category is based on the degree of automation, which can be divided into fully automatic and semi-automatic smokers. Fully automatic smokers have PLC automatic programmable control, allowing for easy adjustment of parameters such as time, temperature, humidity, and exhaust size. They also have a user-friendly interface for monitoring and displaying the operating status of the equipment. On the other hand, semi-automatic smokers offer the option to use imported or domestic electrical components based on customer requirements, which can help save on purchase costs.

The second category is based on the heating source, with two options: steam heating and electric heating. Steam heating is suitable for users with boilers or steam generators, while electric heating uses electric heating tubes for drying, smoking, and coloring. Electric heating is commonly used in food processing plants and requires three-phase electricity, while steam heating is widely used in small family workshops, franchise stores, and small restaurants, and only requires two-phase electricity.

The third category is based on the smoke generator device, which can be either built-in or external. Built-in smoke devices have an electric heating tube within the smoke box, while external smoke devices are fully functional smoke stoves. The choice between the two depends on the desired drying temperature and the desired color depth of the product. The smoking device in the smoker structure can use wood chips or brown sugar to produce smoke, and the temperature during drying will determine the depth of the color.

The fourth category is based on the model and capacity of the smoker equipment manufacturer. There are various models available, such as 30 type, 50 type, 75 type, 100 type, 150 type, 200 type, 250 type, 500 type, and 1000 type. Customers should consider their own output requirements and choose the model that best suits their needs.

In conclusion, when selecting the right smokehouse oven, it is important to consider the degree of automation, heating source, smoke generator device, and the model and capacity of the smoker machine. By carefully considering these factors, customers can make an informed decision and choose the oven smoke house that best meets your specific requirements.

Which smoking way should I choose? Built-in smoking or external smoking?

Choosing between built-in smoking and external smoking for your oven smoke house depends on several factors.

Built-in smoking involves mixing smoking material and sugar in the built-in smoking box. The smoking time and temperature can be set on the control panel, and the electric heating tube heats the smoking material. The combustion process evenly spreads volatile substances produced by incomplete combustion, resulting in smoked and colored food. This method is convenient and straightforward, as everything is contained within the oven. However, it may have limitations in controlling smoke size and concentration.

On the other hand, external smoke generation follows a similar process but offers more control over smoke size and concentration. The smoke is generated outside the oven and then enters the flue through a blower. Before entering the furnace body, the smoke is filtered to reduce the content of certain substances. This method allows for greater customization of the smoking process and may result in a more refined end product. However, it requires additional equipment and may be more complex to set up and operate compared to built-in smoking.

Ultimately, the choice between built-in smoking and external smoking depends on your specific needs and preferences. If you prioritize convenience and simplicity, built-in smoking may be the better option. However, if you value greater control and customization in the smoking process, external smoking may be worth considering, despite the additional complexity.

What is the available smoked wood for industrial smoke house ?

For your oven smoke house, we recommend using popular varieties such as cherry, hickory, apple, beech, birch, oak, and maple for optimal smoking results. Additionally, you can consider mesquite, pecan, alder, cherry, and plum as alternative options. However, it is important to avoid using pine, elm, peach, and apricot wood as they have high resin content and tend to produce black smoke. Similarly, persimmon trees and mulberry trees should be avoided as they produce an odor that is not suitable for use as smoked wood.

What is the special attention items for the industrial smokehouse?

Vent Management: It is crucial to avoid opening all the vents of the oven smoke house to prevent open flames. In case of an open flame, it is essential to promptly turn off the fan and vents to prevent any potential hazards.

Wood Chip Addition: During the smoking process, it is strictly prohibited to open the door of the smoke chamber for adding wood chips. Before adding wood chips, the equipment should be stopped for a minimum of 2 minutes to ensure safety.

Cleaning Pump Usage: The cleaning pump should never be left idle without water. It is important to always have water running through the cleaning pump to prevent any damage or malfunction.

Protection from Water: It is crucial to prevent water from splashing onto the smoker control box and computer. Extra care should be taken to ensure that these components remain dry at all times to avoid any electrical issues or damage.

By adhering to these special attention items, you can ensure the safe and efficient operation of the oven smoke house.

What is the daily maintenance for the industrial smokehouse?

Before starting each shift, carefully inspect the steam gas source, compressed air gas source, and power supply to ensure they are functioning properly.

Check the wood pellet smoke generator at the beginning of every shift. Ensure that it is producing normal smoke and there is no open flame. Additionally, check if there are enough wood pellets for operation.

Conduct a thorough inspection of the entire machine for air leakage, smoke leakage, and any other defects during each shift. If any issues are identified, they should be promptly repaired.

Take necessary precautions to protect the electrical control system, especially the computer. Avoid allowing water to enter the control box and computer to prevent any potential damage.

After each shift, clean the interior of the oven smoke house. Remove any soot or residue from the wood pellet smoke generator in a timely manner.

What is the regular maintenance for the industrial smokehouse?

Regular maintenance is essential to ensure the optimal performance and longevity of your oven smoke house. Please follow the below maintenance guidelines:

Bearings: Every six months, fill the bearings of the equipment’s motor, fan, smoke generator, and blower with calcium-based high-temperature grease. This will help lubricate the bearings and prevent any potential issues.

Damper Baffle: Regularly remove soot and oil buildup between the damper baffle and the damper to ensure smooth opening and closing. This will prevent any obstruction and ensure proper airflow.

Smoke Generator Filter: Clean the smoke generator filter frequently to prevent clogging and maintain efficient smoke generation. This will help ensure consistent smoke production and enhance the smoking process.

Electrical Components: Regularly check electrical components, instruments, and measurement and control devices to ensure their normal operation. It is recommended to have these inspections and maintenance conducted by professional electricians to ensure safety and proper functioning of the equipment.

By adhering to these maintenance practices, you can ensure the smooth operation and prolong the lifespan of your smokehouse oven.