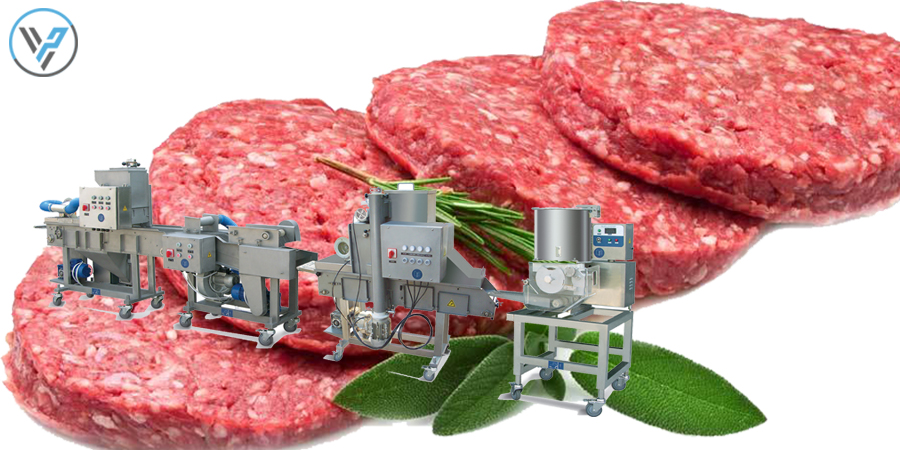

A patty forming processing line includes forming, battering, preduster, breading, frying, air cooling, IQF machines, which is an ideal line for making hamburgers patties, chicken nuggets, fish fillet, chicken strips, etc. This line has a wide application for butchers, super and hypermarkets, butcher shop, take away shop, fast food, deli, restaurant, food processors.

Here are 7 points mentioned when ordering one patty forming processing line, let’s consider comprehensively in order to make the most wise choice for expanding the fast food industry:

1.Easy to Operate

Concluding forming, battering, preduster, breading, so big process line could be easily operated. Just pressing the button on the operation panel by only one labor. You could easily stop the working by pressing the emergency button when any possible danger happen for every machine part for the line. In order for your easy operation, machine manual and video will be sent when machine delivered.

2.High Productivity

One hour, you could easily get 2,100 hamburgers & 4,200 chicken nuggets by this small patty forming line. You can count on a productivity 100x max increase. This small patty forming line is a must to have for hamburger and chicken processors all over the world.

3.Multi Raw Material Application

You are familiar with chicken, beef, pork fillet and patties, why do not increase some vegetables and seafood to your patties to innovate new business? VER patty forming machine could not only form different minced meat, like beef, chicken, pork, mutton, also could form seafood (fish, shrimp), vegetables(potato, pumpkin, bean), Yam(sweet potato, purple sweet potato), and cereal(corn, rice, glutinous rice), etc.

4.Multi Shapes and Sizes Process

Except round patties, you could get squares, triangle, heart shape, ovals patties. So hamburger patty, chicken nuggets, chicken or beef steak, pumpkin or potato patty could be made to meet different crowd requirements by this patty forming processing line. Different shapes could be customized by changing forming molds.

5.Continuous Production

Forming machine could be easily connected to battering-breading machine to produce hamburger patties, also by linked to preduster-battering-breading machine, chicken nuggets could be produced. Different machines could be formed together to meet different process requirements.

6.Easy Cleaning

Cleaning is always very important in food processing industry. With whole parts made of stainless steel 304, operation panel fully water proof, you could rinse the whole patty forming processing line directly with water. Even the machine bracket is made of cylindrical instead of square tube, you could make daily cleaning much easier without leaving any corner.

7.After Sale Service

-We highly recommend every forming/battering/breading machine should be inspected every 3 months to avoid any possible machine down.

-VER Offers our customer long life technical and maintenance support.

-Any questions will be replied within 24 hours.

-Engineers are available overseas for better after sale assistance and support.

Now you should know basic tips of what to be considered when ordering one patty forming processing line, contact us for more professional recommendation of the whole patty forming solutions and get free quotation!

Leave a Reply